The effect of pin coplanarity on soldering of electronic components-Fitech Solder Paste

The effect of pin coplanarity on soldering of electronic components

In SMT (Surface Mount Technology), solder joints are an important medium for connecting electronic components to the PCB (Printed Circuit Board), and solder failure is one of the most common electronic component failures. It is therefore vital to ensure reliable soldering of electronic components. One of the most important factors affecting solder reliability is the coplanarity of the device pins.

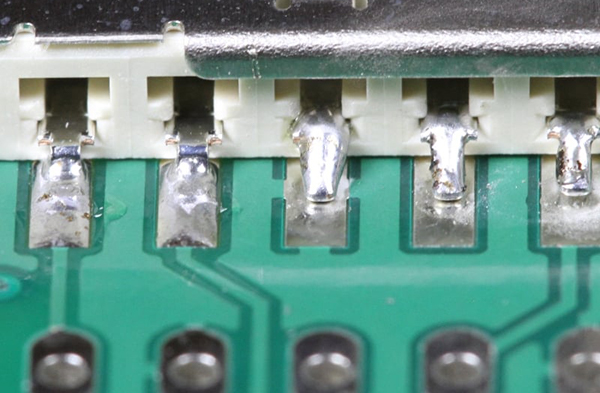

When all the pin endpoints of a device are in the same plane it is called device pin coplanarity. However, due to forming stresses on the extension pins during device fabrication and the effects of various external forces during storage and transport, it is common for the extension pins to be soldered out of plane. This difference in co-planarity needs to be compensated by solder to fill the square to form a reliable solder joint.

Soldering faults such as pin dummy and missing solder can occur when the soldered parts of a device are not coplanar. To ensure the reliability of solder joints, device pin co-planarity needs to be tested. Currently, there are two main test methods: the fixed measurement method and the regression surface test method.

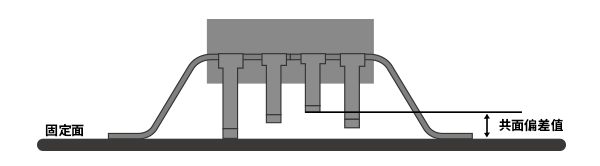

Fixed surface measurement method:

A fixed surface is a plane consisting of the three solder vertices furthest vertically from the bottom of the device package, where the vertical projection of the component's centre of gravity must fall within the triangle formed by these three solder vertices. The industry often uses the fixed plane measurement method to evaluate the co-planarity of the solder terminals of a device. For BGA devices, the three highest balls hold up the device body and form a fixed plane (the vertical projection of the centre of gravity of the BGA body lies within the triangle formed by these three balls), the maximum distance of the other balls from this plane is the co-planarity deviation value.

Regression surface test method:

The regression plane is the plane that passes through the weld vertices furthest vertically from the bottom of the device body and is parallel to the optimum plane formed by the vertices of all weld joints determined by the least square method.

How can I avoid devices with non-co-planar pins?

1. Avoid extrusion packaging, drops and impacts during the transport and handling of extended foot devices.

2. The reuse of the cast material of the production line needs to be 100% inspected and put back into use after the whole foot if necessary.

3.BGA device placement, equipment open global recognition function, the size of the ball, the lack of ball bad automatic interception detection.

4. The use of smaller pitch ultra-micro solder paste is able to improve the situation of device pins not co-planar to a certain extent. As the super micro solder paste can improve the soldering accuracy and solder joint quality, thus reducing the gap between the device pins and PCB pads and increasing their connection strength, it can offset the impact of device pins not co-planar to a certain extent and improve the reliability and accuracy of the package.

Shenzhen Fitech ultra-fine solder paste can improve the problem of non-collinearity of device pins, welcome to call us for more information.

Back to list

Back to list