Fatigue Life Model of Solder Joint_Shenzhen Fitech

Fatigue Life Model of Solder Joint - Shenzhen Fitech

The soldering of components generally requires the use of solder pastes as the connecting phase, which will form solder joints after reflowing. Due to various impacts that are often encountered in the daily use of components, the stress at the solder joint continues to accumulate. Stress can take many forms, such as thermal stress caused by thermal cycling and mechanical stress caused by stretching. The accumulation of stress can cause slow fatigue of solder joints, which can hurt the service life of solder joints.

Fatigue life test

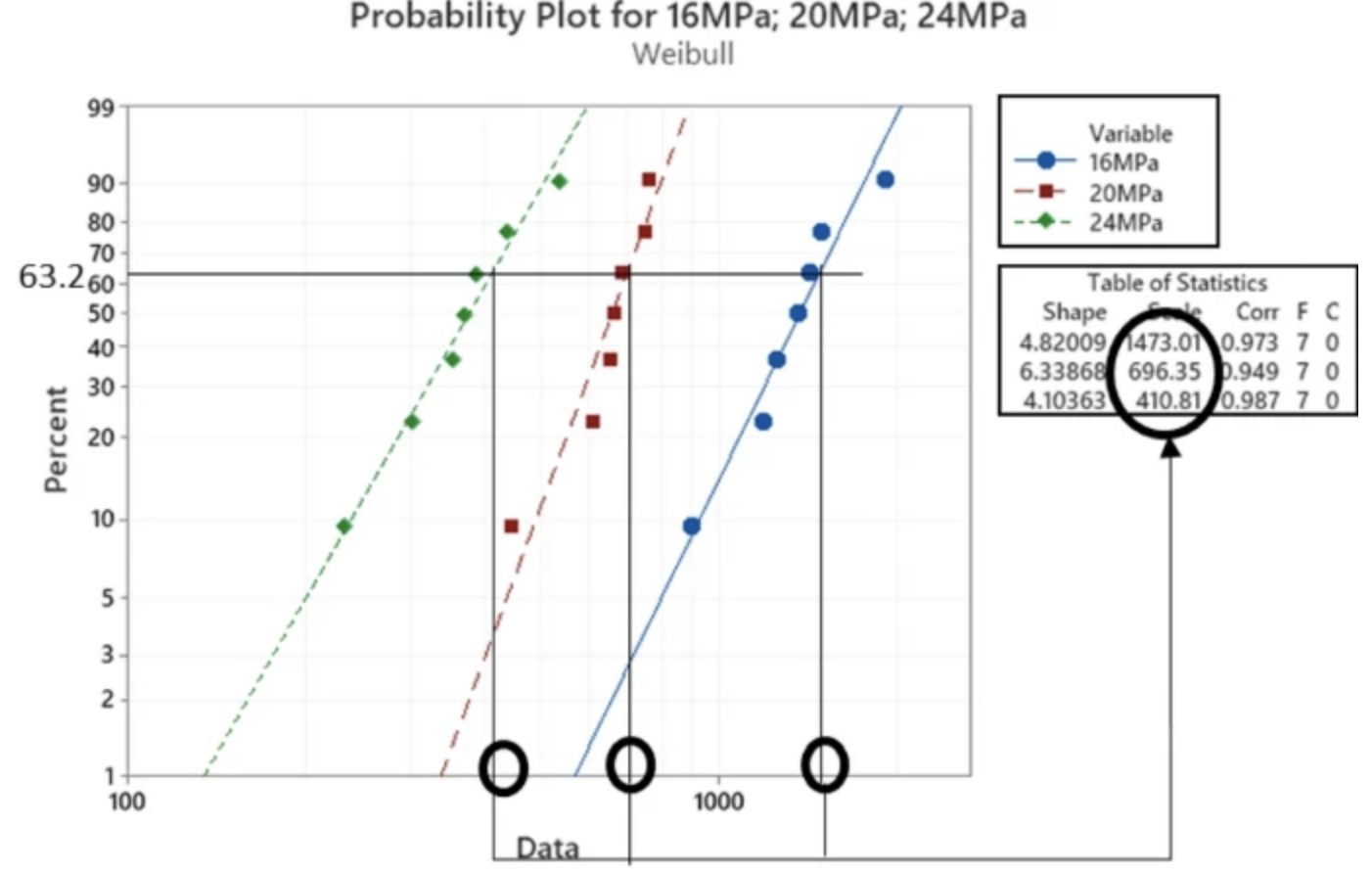

Since the harm caused by stress cannot be underestimated, it is necessary to deepen the understanding of the fatigue behavior of solder paste alloys. Hani et al. adopted accelerated fatigue experiments to test the fatigue life of SAC305 solder joints under actual conditions. They used three vibration amplitudes (16MPa, 20MPa, and 24MPa) and a test temperature of 25°C as experimental conditions. After obtaining experimental data, Weibull distribution analysis was performed.

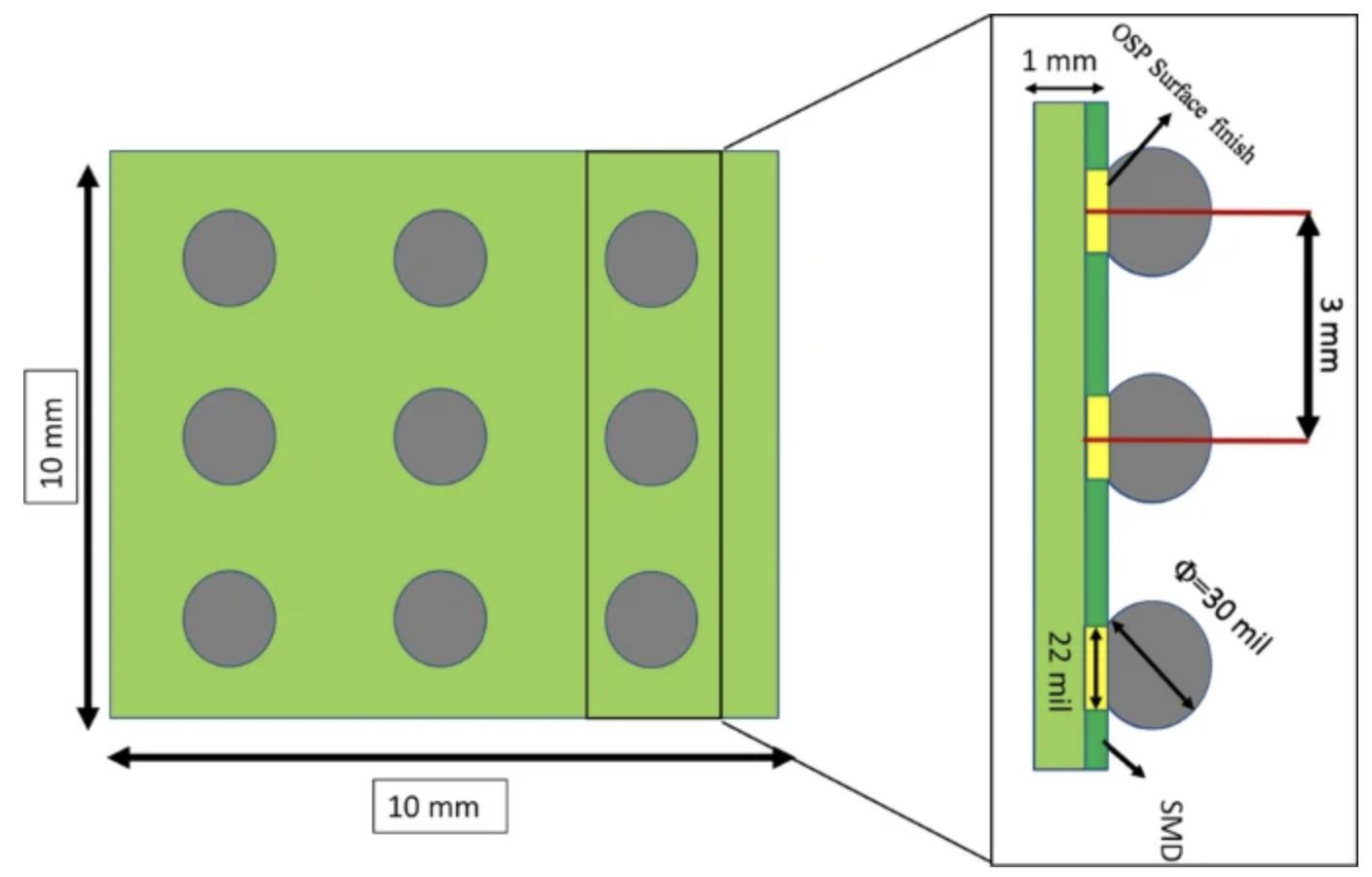

Figure 1. Fatigue life testing vehicle.

Experimental result

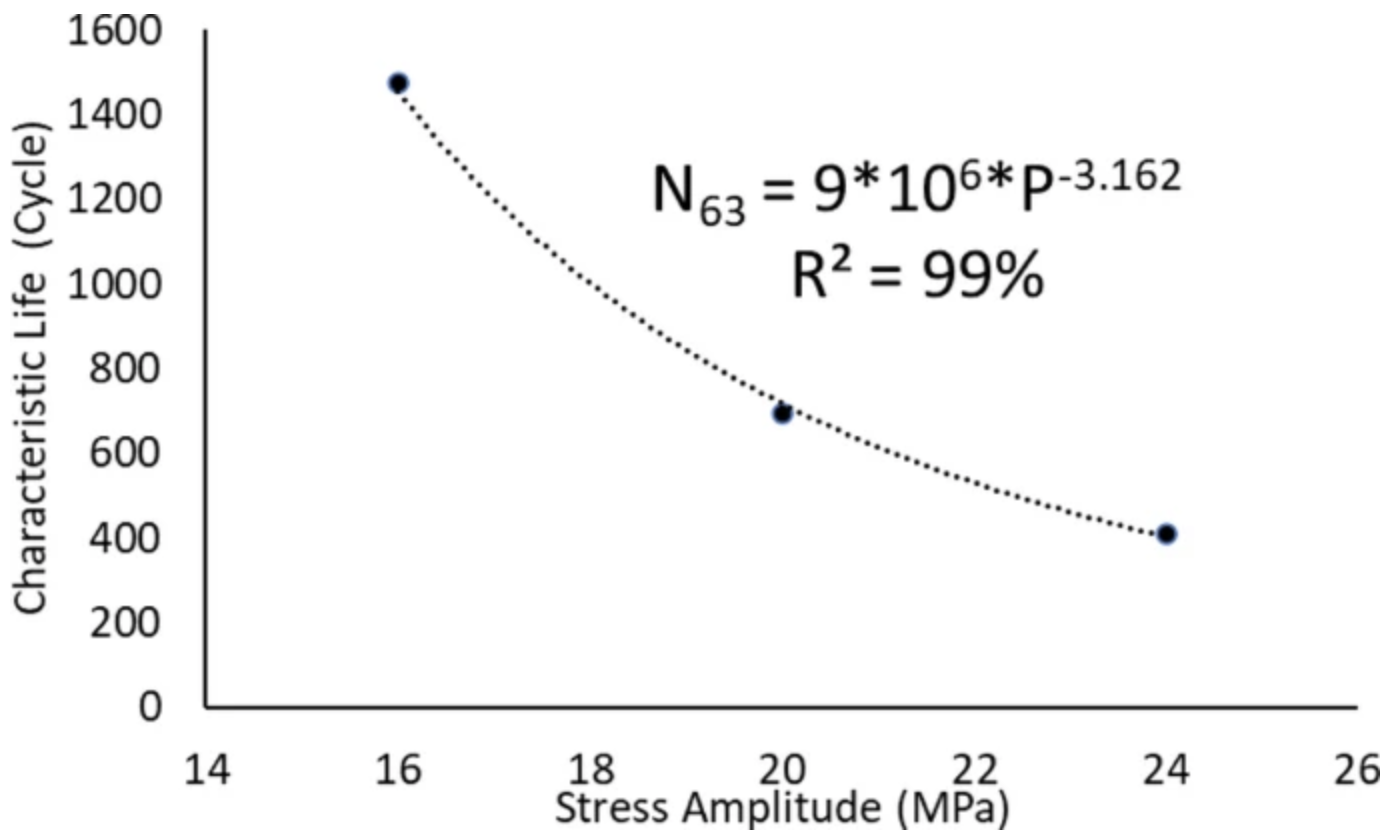

Hani et al. used the following formulas to relate the fatigue life and temperature of SAC305 solder joints. The formulas state the number of cyclic stresses required (N63) for 63% of the test sample failing. The formulas have high applicability and can be used to analyze fatigue life at various temperatures. P represents the stress amplitude, R (t) represents the reliability model, and T is the temperature.

Figure 2 shows the Weibull probability diagram of SAC305 solder joints under different stress amplitude cycles at 25℃. It can be clearly seen that when the stress amplitude increases, the fatigue life of the solder joint decreases. After identifying the relationship between characteristic fatigue life and cyclic stress amplitude, the fatigue life of solder joints can be modeled (Figure 3). In addition, according to the fatigue life formula, it can be inferred that as the temperature increases, the stress on the solder joint increases, and the characteristic life rapidly decreases.

Figure 2. Weibull probability of SAC305 solder joints subjected to different load cycles at room temperature.

Figure 3. SAC305 solder joint stress life model at room temperature.

High fatigue life solder pastes

Shenzhen Fitech is committed to providing customers with high-reliability solder pastes. Fitech’s low-temperature FL170 Series, medium-temperature SAC305, high-temperature SnSb10, and other solder pastes have excellent mechanical strength and drop resistance and are suitable for a variety of packaging fields, such as optoelectronic displays, aerospace, automotive electronics, and so on. Welcome to contact us for more information.

Reference

Hani, D.B., Athamneh, R.A., Abueed, M. & Hamasha, S. (2023). Reliability modeling of the fatigue life of lead-free solder joints at different testing temperatures and load levels using the Arrhenius model. Scientific Reports, 13.

Back to list

Back to list