Nucleation and Growth of Ag3Sn in Lead-Free Solders_Shenzhen Fitech

Nucleation and Growth of Ag3Sn in Lead-Free Solder_Shenzhen Fitech

Due to the ability of Ag to provide better conductivity and wettability for solder pastes, many low and medium-temperature lead-free solders currently contain a small amount of Ag to optimize solder joints. The solder pastes containing Ag, such as SnAg3Cu0.5 and SnBi47.6Ag0.4, typically produce better solder joints than SnCu and SnBi series solder pastes. In these Ag-containing solders, intermetallic compounds (IMCs) Ag3Sn are often generated in the form of eutectic reactions during the solidification process. Many studies have shown that the growth of primary Ag3Sn plates can have adverse effects on solder joints. Thus, it is necessary to analyze the growth mechanism of Ag3Sn in the solder layer.

Sample preparation and tests

Cui et al. pressed different solder alloys into 30μm foils at high temperatures, then add flux and reflow to form a diameter of 500μm. The solder sample will undergo DSC experiments to heat and then cool. By analyzing the endothermic peak, the liquidus temperature of Ag3Sn can be understood.

Ag3Sn undercooling

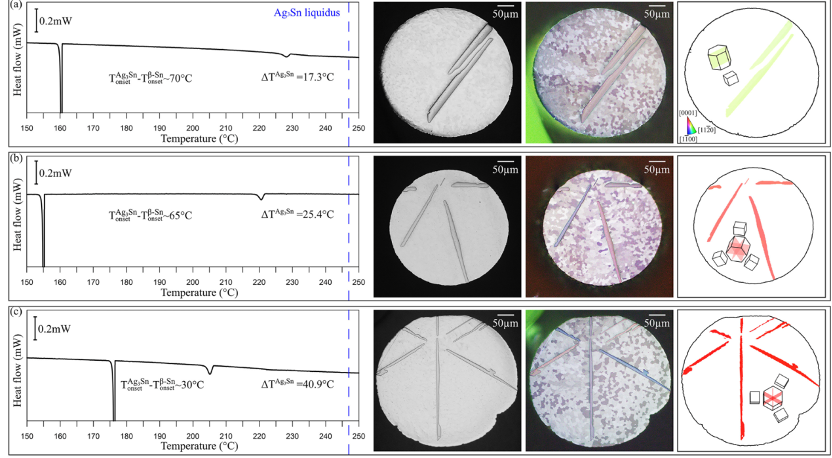

The following figure describes the effect of undercooling on the growth of primary Ag3Sn in Sn95Ag5 when the cooling rate is 5K/min. According to the results, the undercooling range of Ag3Sn nucleation is approximately 17-68 ° C. In addition, the growth shape of Ag3Sn at the minimum undercooling (<20 ° C) is a single crystal plate. As the undercooling deepens to 25°C, three branching Ag3Sn plates are formed in polarized light imaging. When the undercooling exceeds 40 ℃, the Ag3Sn plates are still branching, but parallel plates may appear. A higher degree of undercooling will cause Ag3Sn and β-Sn to exhibit different nucleation temperatures, providing a longer window period for the growth and coarsening of Ag3Sn.

Figure 1. The microstructure of Ag3Sn in SnAg5 at different undercooling temperatures.

The effect of coolind rate on Ag3Sn

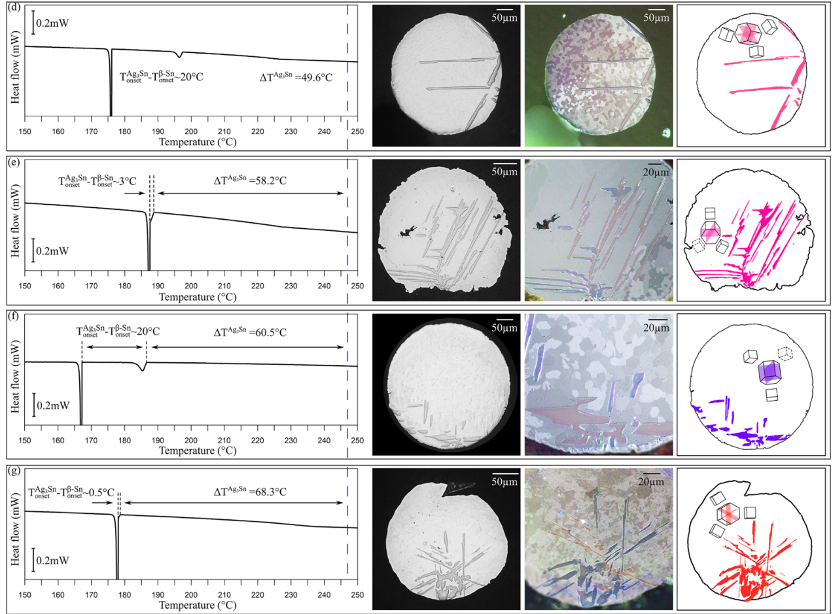

When the cooling rate is slow, Ag3Sn will grow in single crystal form in SnAg5 balls. As the cooling rate during the reflow process increases, more Ag3Sn growth occurs in the form of twinning. Obviously, twinning tends to form at lower temperatures as well as at deeper undercooling. In addition, it can be seen from Figure 2(b) that as the cooling rate increases, the initial temperature of Ag3Sn nucleation will be lower.

Figure 2. Nucleation of Ag3Sn in SnCu5 at different cooling rates.

Ag3Sn growth after soldering on copper substrates

Since the interference of β- Sn nucleation is less, the average Ag3Sn undercooling of SnAg5 is deeper than that of the other three types of solder. Moreover, Cui et al. found that copper substrates can play a catalytic role in the nucleation of solder Ag3Sn. When soldering with copper substrates, the nucleation onset temperatures of Ag3Sn are significantly higher than the corresponding solder balls, and the nucleation temperature of all solder joints is higher than the liquidus temperature of Ag3Sn.

Figure 3. Nucleation onset temperatures of Ag3Sn in different solder materials.

Shenzhen Fitech is a manufacturer dedicated to producing lead-free solders for semiconductors. Please feel free to contact us for further inquiries regarding solder issues. Fitech’s lead-free solder products cover the solder paste from low to high melting temperature. Welcome customers with soldering material requirements to cooperate with us

Reference

Cui, Y., Xian, J.W., Zois, A., Marquardt, K., Yasuda, H. & Gourlay, C.M. (2023). Nucleation and growth of Ag3Sn in Sn-Ag and Sn-Ag-Cu solder alloys. Acta Materialia, vol.249.

Back to list

Back to list