Classification and selection of wave soldering flux-Fitech Flux

Classification and selection of wave soldering flux-Fitech Flux

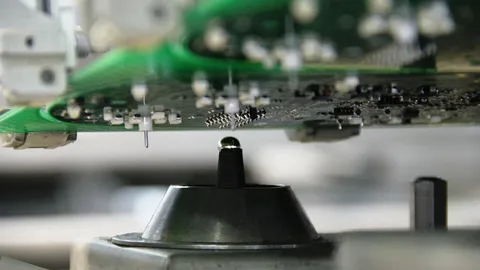

Wave Soldering is a common PCB soldering technique in which electronic components and boards (pre-applied flux in the soldered area of the board) are placed on a wave of melted solder to make a soldered connection.

Wave soldering usually requires the use of flux to improve solder quality and efficiency. Different types of fluxes have different properties and uses, so it is important to choose the right flux. This article will introduce the classification and selection of wave soldering fluxes.

J-STD-004 standard based on the activity of the flux will be divided into high activity H, medium activity M, low activity L three, the most widely used in the industry is the L type, also known as no-clean flux.

No-clean flux

No-clean flux has low activity and limited active agent content, and some flux residues on the product after soldering are not enough to cause corrosive short circuits or open circuits.

No-clean flux although its residues are not highly corrosive, but some flux residues are not dry enough to have a strong adhesion capacity, adsorption and adhesion of solid particles in the environment, some particles have electrical conductivity, and eventually the formation of electrical pathways, resulting in failure.

Highly corrosive fluxes

Highly corrosive fluxes are highly corrosive, and the residues must be thoroughly cleaned after welding, otherwise chemical corrosion failure will occur. In order to facilitate cleaning, high activity flux active agents are mostly inorganic acids, dissolved in water (easy to clean), low activity flux active agents are mostly organic acids or organic acid salts, generally insoluble in water, not easy to clean.

How to choose the right flux?

1. If the product needs to be cleaned, it is recommended to choose a water-washing flux for easy cleaning. If you choose no-clean flux, cleaning after welding increases the difficulty, and requires the use of professional cleaning agents (mostly alkaline solutions), and heating to enhance its solvents chemical reaction ability, the cost increases quite a lot.

2. Select the flux suitable for wave soldering process, you need to determine the type and content of active agent according to the welding temperature and welding time. In general, low active no-rinse fluxes are suitable for most wave soldering applications.

3. If the product requires high solder quality and reliability, it is recommended to choose a high active flux, but attention needs to be paid to the residue cleaning process and cost.

4. If the soldering material has an impact on the choice of flux, it is necessary to choose the appropriate flux according to the characteristics of the material. For example, for copper substrates, it is recommended to use highly reactive fluxes, because copper reacts unstably with tin.

Special attention is paid to the residue of flux after wave soldering sometimes can not be cleaned: the use of organic solvents or water-based cleaning agents can not effectively remove the residue.

This is because the wave solder flux sprayed after being heated, the activity is stimulated and remove part of the oxide layer, in contact with the tin wave when the flux instantly by the high temperature tin wave impact and vaporization, if the PCB solder resist layer curing is not complete, vaporized flux will be drilled into the PCB solder resist layer, the phenomenon of cleaning can not be removed. Prevention of such problems is the PCB incoming inspection "bleaching tin test". For the problem board has appeared, because its nature does not affect the product function and reliability, in principle, can ignore its existence, for the appearance of demanding products, you can use a hot air gun to heat the product, while heating wipe clean, you can clean the board to a certain extent, but the eradication is extremely difficult.

Fitech Flux

Shenzhen Fitech Co., Ltd. FNC-3120, FWF-5100 series fluxes are suitable for BGA pre-flocking ball flux, pre-deposition solder flux, stabbing crystal transfer flux and other application scenarios. Welcome to inquire for more contents.

Back to list

Back to list