Ultrasonic-Assisted Bonding in Si/Cu Solder Joint _Shenzhen Fitech

Ultrasonic-Assisted Bonding in Si/Cu Solder Joint _Shenzhen Fitech

Silicon is a common crystal material with a low coefficient of thermal expansion in modern microelectronics. It is widely used in advanced packaging fields such as power devices and 3D packaging. However, as the packaging density increases, the heat generation of packaged devices increases significantly, which declines the reliability of silicon. Therefore, some industry insiders have attempted to solder Si substrates with high thermal conductivity copper to improve heat dissipation performance. However, ordinary alloy solder is difficult to wet on the silicon surface, which requires a new welding approach.

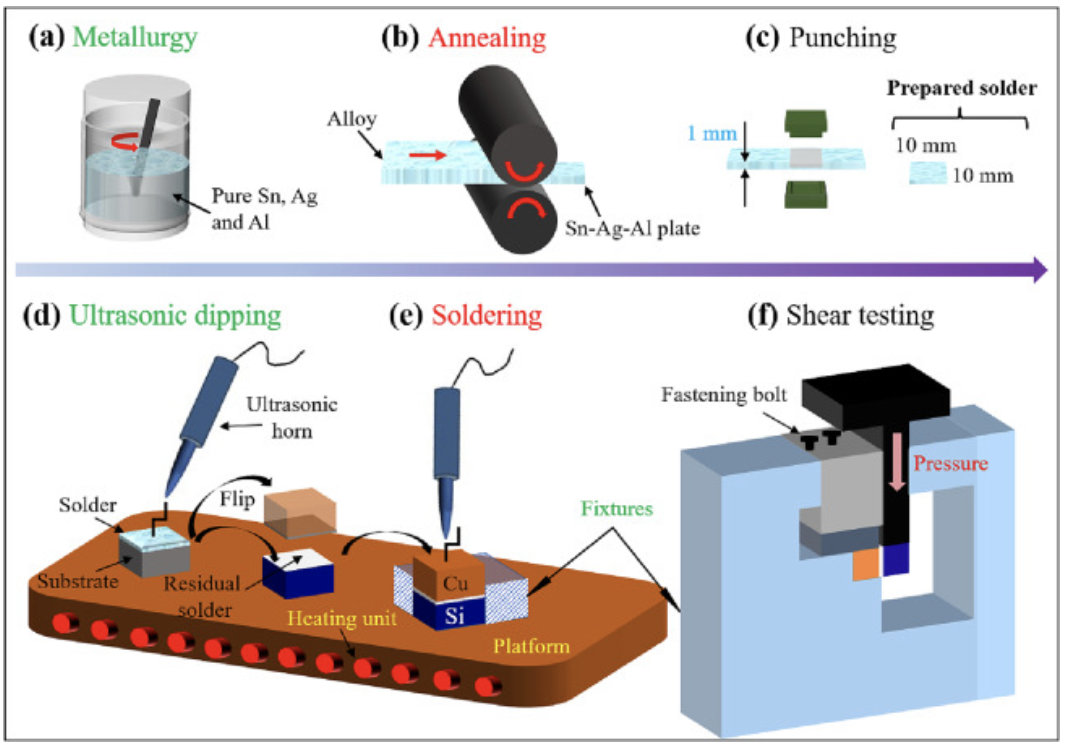

Ultrasonic soldering can cavitate in liquid solder. Bubbles nucleate and grow in molten solder and finally collapse near the solid-liquid interface. High temperature and pressure generated by ultrasonic can destroy oxides and promote wetting between solder and base material. Hence, flux is not required for this scenario. In order to gain a deeper understanding of the role of ultrasound in soldering, Li et al. used Sn3.5Ag4Al solder to metalize Si and achieved the interfacial bonding between Si and Cu by ultrasound.

Figure 1. Ultrasonic soldering processes.

2.1 Microstructure

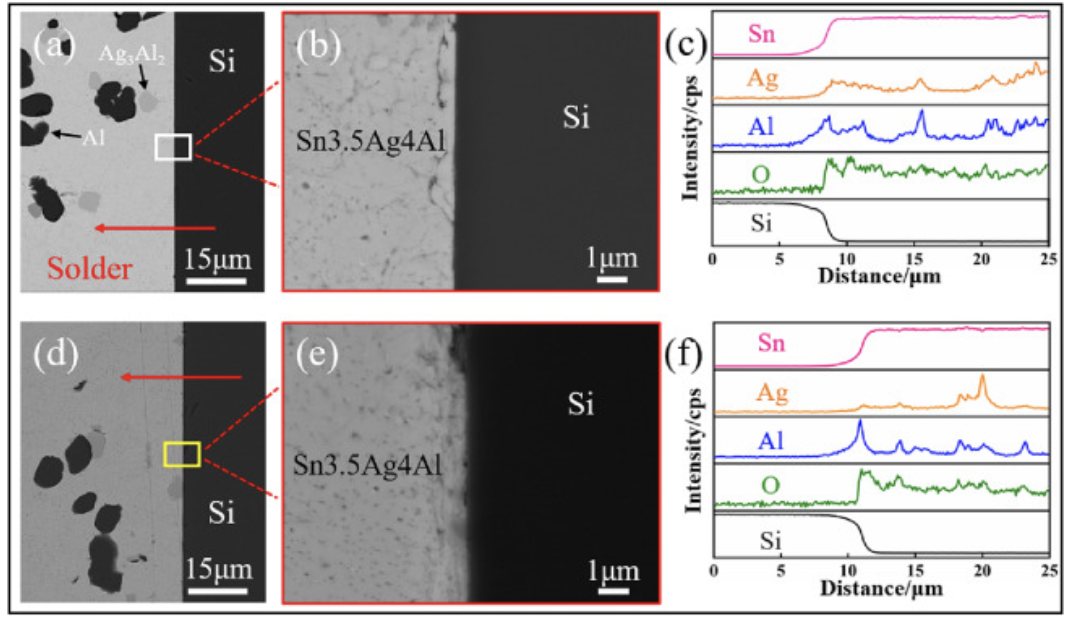

From Figure 2, it can be seen that both ultrasonic vibration times can cause interfacial bonding between Si and Sn3.5Ag4Al solder. However, after 20 seconds of ultrasonic vibration, the interface of the solder/Si is straight and there is no obvious reaction layer. After the ultrasonic dipping time increased to 50 seconds, the interfacial reaction started. From observations, the enrichment of Al and O occurred at the solder/Si interface, indicating the formation of amorphous Al2O3 compounds. Besides, Li et al. tried to apply solder to the Si substrate without ultrasonic assistance, and the result showed that Si and solder could not be bonded.

Figure 2. Microstructure of solder/Si interface under different ultrasonic vibration times. (a-c):20s, (d-f):50s.

When the ultrasonic treatment time is 2s, the Cu/solder interface is relatively straight. CuAl2 is formed at the interface, which is attributed to the preferential reaction between Cu and Al. However, the solubility of solder and Cu is insufficient, and the distribution of CuAl2 is not continuous. As the ultrasound time increases, the distribution of CuAl2 at the interface gradually increases and becomes more continuous. When the ultrasound time is 12s. The dissolution pits appeared at the solder/Cu interface, indicating that the Cu solder pad was severely eroded by ultrasound. It is worth noting that CuAl2 has no significant effect on the strength of solder joints due to the ultrasonic effect.

Figure 3. Microstructure of the solder/Cu interface under different ultrasonic vibration times. (a)2s, (b)6s, (c)12s.

2.2 Mechanical strength

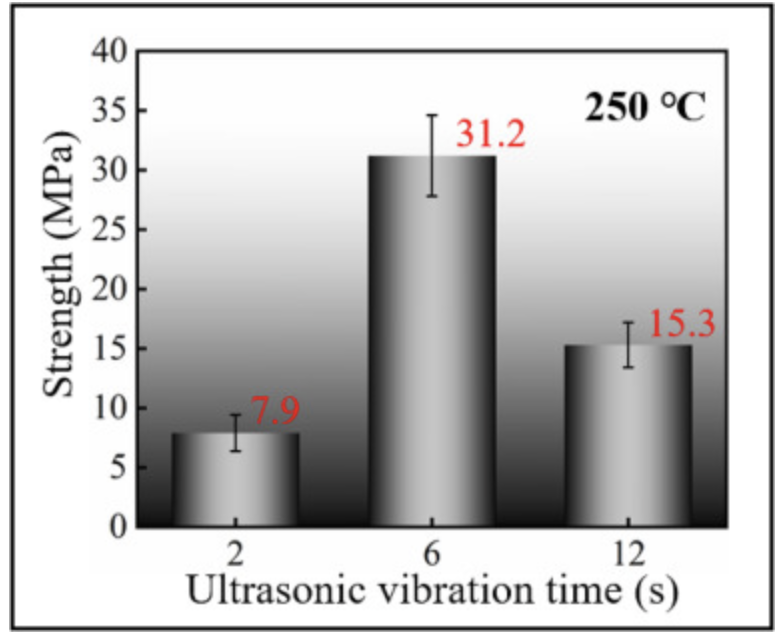

As the ultrasonic vibration time increases, the mechanical strength of Si/Cu solder joints shows a trend from increasing to decreasing. If the ultrasonic time is short, the effective bonding area between the solder and Cu is small. When the ultrasound time is 6s, the CuAl2 crystal at the solder joint was finer, thereby enhancing the solder joint. A longer ultrasound time can lead to the growth of Cu6Sn5, and voids appear on the surface of Cu6Sn5. As a result, the solder joint strength is weakened.

Figure 4. Shear strength of Si/Cu solder joints under different ultrasonic vibration times.

Shenzhen Fitech can provide customers with various types of lead-free soldering materials, including low-temperature, medium-temperature, and high-temperature solder paste products, which can be used for microelectronics packaging. Welcome customers with the soldering material requirement to cooperate with us.

Li, W.Z., Ding, Z.J., Xue, H.T., Guo, W.B., Chen, C.X., Jia, Y. & Wan, Z. (2023). Interfacial bonding mechanisms in ultrasonic-assisted soldered Si/Cu joint using Sn-3.5Ag-4Al solder. Materials Characterization, vol.199.

Back to list

Back to list