Different Anisotropic Conductive Adhesive(ACA) on UHF RFID tag reliability impact-Shenzhen Fitech

Different Anisotropic Conductive Adhesive(ACA) on UHF RFID tag reliability impact

Radio Frequency Identification (RFID) is an emerging technology for identification and security applications that consists of a reader and an RFID tag attached to the identified object. With RFID technology, multiple objects can be identified simultaneously using radio waves without the need for human assistance or visual connection to a reader.

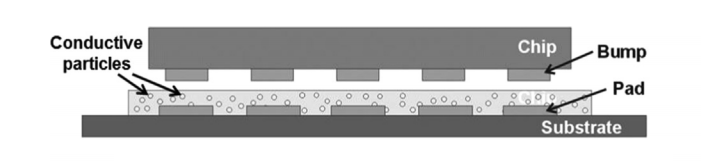

Anisotropic Conductive Adhesive(ACA) is an alternative to solder for finer pitch applications and is more environmentally friendly because the bonding process involves fewer processing steps than solder. ACA is usually heated using hot-pressure soldering.

Figure 1 shows a typical bonding process for ACA flip-chip interconnects using anisotropic conductive adhesives.

RFID tags are used in terminals that may be exposed to a variety of environmental conditions that may compromise their reliability, making reliability studies critical, and accelerated life testing (ALT) is widely used in reliability studies. At the same time, polymer interconnects (e.g., ACA connectors) are susceptible to stress caused by changes in factors such as high temperature and humidity. Therefore, temperature cycling tests and constant humidity tests are widely used for reliability studies of ACA connectors.

Reliability test method:

RFID tags are subjected to temperature cycling tests and constant humidity tests. Both of these tests are standard tests commonly used in electronic applications. Compare the failure times of RFID tags with different ACAs in the two tests.

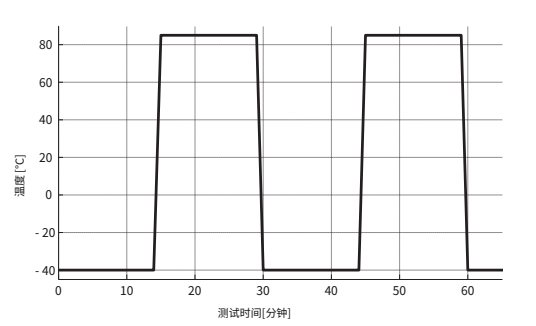

The temperature cycling test is conducted according to JEDEC standard JESD22-A104D [26]. The temperature cycling time is 30 minutes from -40°C to 85°C. As shown in Figure 3, the exposure time at the extreme temperature was 14 minutes and the transition time was 1 minute. The humidity level in the test chamber is not controlled during the temperature cycling test. Samples were tested for 3000 cycles.

Figure 2. Temperature profile of temperature cycling test.

The constant humidity test was performed according to IPC standard IPC-TM-650 2.6.3.1E. The samples were tested under the following conditions: constant temperature of 65°C and constant humidity of 90% RH for 4000 hours.

Temperature cycling test:

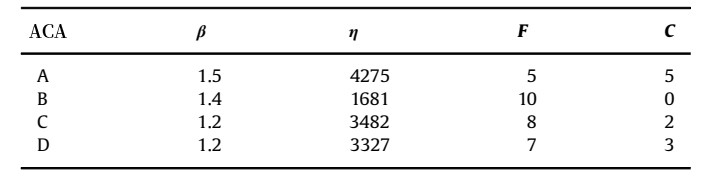

Table 1. Shape and scale parameters of the Weibull distribution in the temperature cycling test.

Where, F: number of failed samples; C: number of samples; β: shape parameter; η: size parameter.

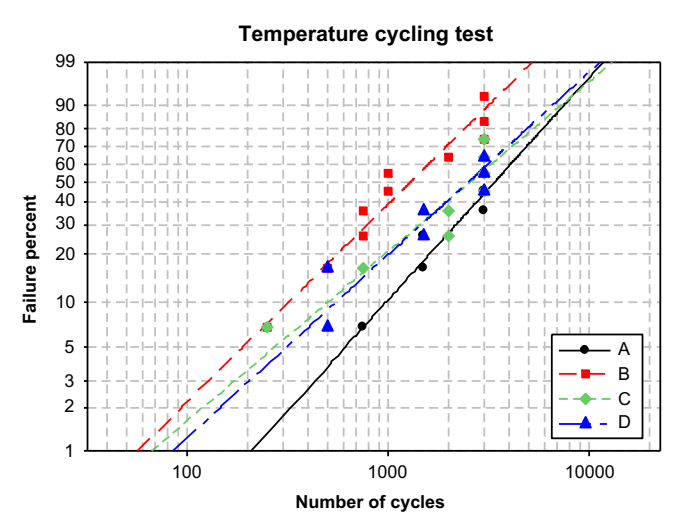

Figure 3. Weibull diagram of temperature cycling test results.

In the Weibull analysis, the tag with ACA B had the lowest scale parameter and the worst reliability in the temperature cycling test. On the other hand, the tag with ACA A had the highest scale parameters and the best reliability.

Constant humidity test:

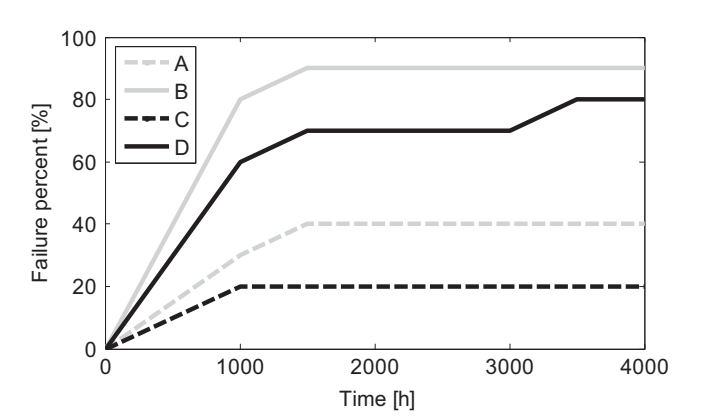

Figure 4. Cumulative failure graph of constant humidity test results for labels with the same bonding parameters as used in the temperature cycling test.

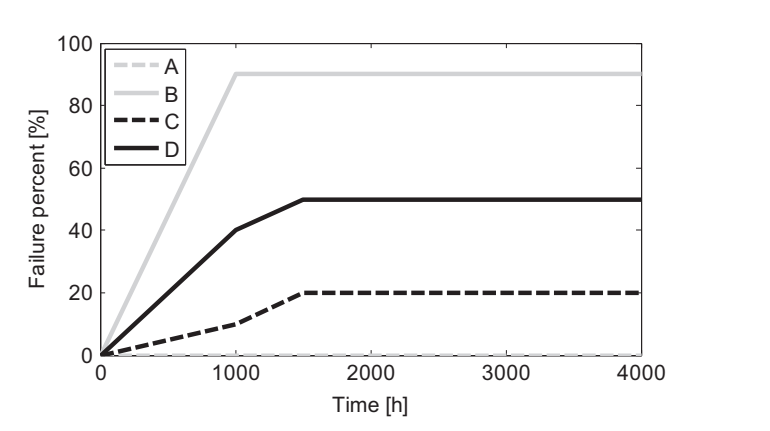

Figure 5. Cumulative failure diagram of constant humidity test results for increased bonding temperature.

In the constant humidity test, the labels with ACA B failed the fastest and were the least reliable. On the other hand, the labels with ACA A and the higher bonding temperature had the best reliability, as none of these test labels failed during the test. It was also observed that ACA C labels were relatively reliable at both bonding temperatures. For ACA B and ACA C, there were no significant differences between the labels at the different bonding temperatures. However, for ACA A and ACA D, it was observed that the labels were clearly more reliable at the higher bonding temperature. This suggests that the curing profile at lower bonding temperatures leads to some undercuring of ACA A and ACA D, which diminishes their reliability in wet conditions.

Conclusion

The reliability of RFID tags using four different ACAs was studied in temperature cycling tests and constant humidity tests. The results show that the choice of ACA material may have a significant impact on reliability.

The ACA A with the largest conductive particles showed the best reliability in both tests. However, this ACA requires a long curing time after attachment, which increases its production time and cost. Therefore, while this ACA has good reliability, it is not practical for many low-cost applications, such as passive RFID tags.

ACA C and D have a very similar matrix composition. In constant humidity tests, ACA C with larger particles is more reliable. Therefore, larger particles appear to improve reliability.

Anisotropic Conductive Adhesive

Shenzhen Fitech Co. Ltd. is committed to providing customers with highly reliable solder paste. Fitech low-temperature metallurgical connection anisotropic halogen-free conductive adhesive can be used in the manufacture of touch screens, smart cards, RFID, Flip chip, FPC and other products.

References

Kirsi Saarinen-Pulli, Sanna Lahokallio, Laura Frisk (2016). Effects of different anisotropically conductive adhesives on the reliability of UHF RFID tags. International Journal of Adhesion & Adhesives, vol. 64, pp.52-59.

Back to list

Back to list