Ag-Decorated Multi-Walled Carbon Nanotubes Improvement for LED Package- Shenzhen Fitech

Ag-Decorated Multi-Walled Carbon Nanotubes Improvement for LED Package- Shenzhen Fitech

Based on the increasingly high requirements for solder strength and thermal reliability in the electronic packaging industry, many solder practitioners have turned their attention to improving the o

verall performance of solder paste. Nanomaterials have always received attention due to their excellent physical and chemical properties. The application of nanomaterials in solder paste is the key to improving the properties of solder pastes. Carbon nanotubes (CNTs) have attracted the attention of many researchers due to their excellent flexibility, thermal conductivity, and conductivity.

Although there has been a lot of research on CNT, combining CNT with solder paste is a novel topic. To investigate the effects of CNT on solder paste, Park et al. prepared 10-20nm Ag-decorated multi-walled carbon nanotubes (Ag-MWCNTs) and doped them into Sn42Bi58 solder paste. Finally, the impacts of the nanocomposite solder paste on the reliability of LED packaging were investigated.

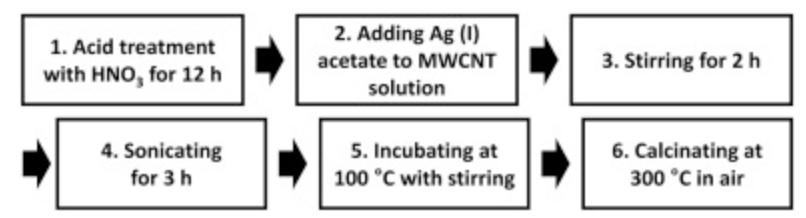

Figure 1. Ag-MWCNT preparation process.

1. Soldering process

Sn42Bi58 solder paste with Ag-MWCNT was placed onto the Cu pad of Al metal PCB. Then, the GaN-type ENIG-LED chip was bonded to the Cu solder pad by thermal compression at 190 ℃.

2. Experimental results

Due to a large number of Bi atoms in Sn42Bi52 solder paste, the Sn-rich phase and Bi-rich phase were formed after reflow. With the diffusion of Cu pad atoms, Cu6Sn5 IMC formed at the interface between the solder and pad. On the side of the ENIG-LED chip and solder, (Cu, Ni) 3Sn4 IMC grew due to the diffusion of Ni.

2.1 IMC thickness

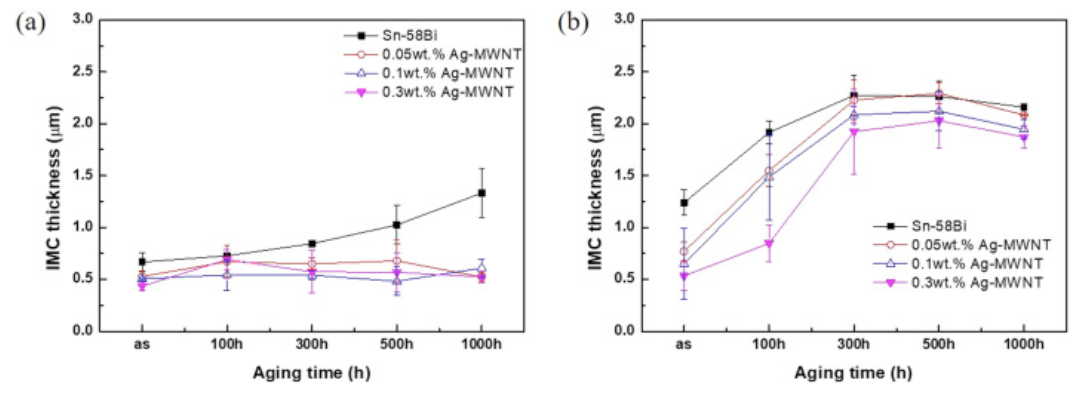

IMC thickness is a critical indicator for determining the reliability of solder pads. Typically, the IMC thickness at the interface between the solder layer and the LED chip increases with aging time. Different amounts of Ag-MWCNT addition resulted in different IMC thicknesses. When the addition of Ag-MWCNT is 0.3wt%, the IMC thickness after aging for 1000 hours is the smallest (Figure. 2a). Similarly, Ag-MWCNT can effectively reduce the thickness of IMC on the side of the solder pad (Figure. 2b).

Figure 2. IMC thickness after aging at 85 ℃. (a): FC LED side; (b): pad side.

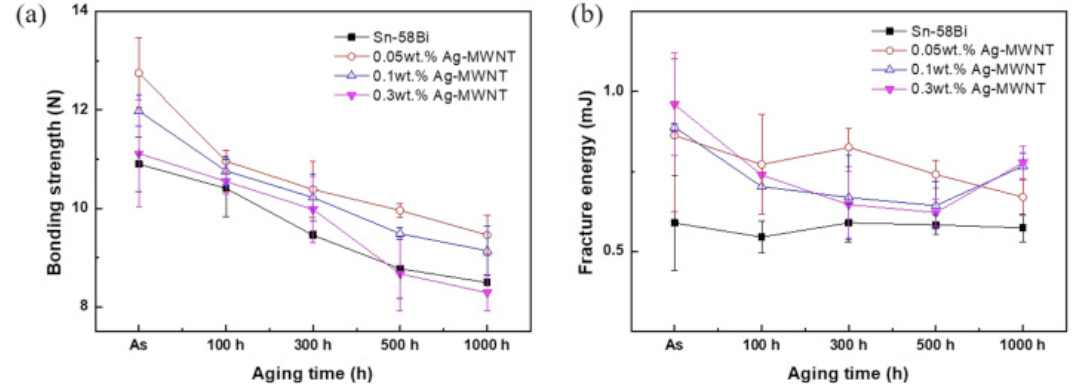

2.2 Bonding strength

Although the bonding strength of solder joints is basically decreasing during the aging process, compared with ordinary Sn42Bi52 solder paste, the bonding strength of Sn42Bi58 solder joints with 0.05wt% and 0.1wt% Ag-MWCNT added was stronger because of the dispersion of Ag-MWCNT in the solder matrix strengthening the solder joints. However, the bonding strength of Sn42Bi58 solder joints with the addition of 0.3wt% Ag-MWCNT was actually the lowest after aging. The reason is that excessive Ag-MWCNT aggregated in the solder matrix.

Figure 3. Bonding strength of solder joints after aging at 85 ℃. a: FC LED side, b: pad side.

2.3 LED chip temperature distribution

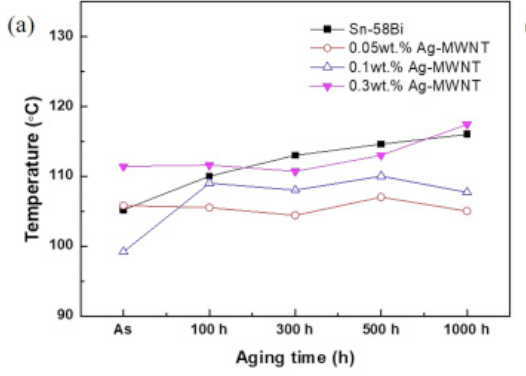

During the aging process, ordinary Sn42Bi58 solder joints brought higher internal temperatures to LED chips. Higher temperatures easily increase thermal stress, which is harmful to the long lifespan of solder joints. The internal temperature of Sn42Bi58 solder joints with 0.05wt% Ag-MWCNT after aging for 1000 hours was the lowest, which is approximately 10°C lower than that of ordinary Sn42Bi58 solder joints. In addition, the excessive doping of Ag-MWCNT resulted in a higher internal temperature of the solder joint due to particle agglomeration.

Figure 3. LED chip temperature.

3. Fitech's nanocomposite solder paste

It could affect the performance of the solder paste in many aspects to add nano and micro size material into it. And that needs a lot of research. Fitech has experience in studying nanocomposite solder paste for many years and has developed a composite low temp. solder paste which is based on Sn42Bi58 solder paste and is enhanced by nano and micro particles. The composite solder paste has better performance in mechanical strength and aging resistance resulting from balancing the alloy component and reducing the Bi-rich phase. Welcome to contact us to know more about our products.

4. Reference

Park, B.G., Myung, W.R., Lee, C.J. & Jung, S.B. (2020). Mechanical, electrical, and thermal reliability of Sn-58wt.%Bi solder joints with Ag-decorated MWCNT for LED package component during aging treatment. Composites Part B: Engineering, vol.182.

Back to list

Back to list