BGA solder joint failure analysis - Cold Soldering and Grape Ball Effect-Shenzhen Fitech

BGA solder joint failure analysis - Cold Soldering and Grape Ball Effect

BGA (Ball Grid Array) is a high-density surface mount packaging technology that replaces the pins of a chip with solder balls and arranges them in a grid pattern on the bottom of the chip, connecting them to the pads on the printed circuit board (PCB) through reflow soldering. However, BGA also has some reliability problems, the most common of which is solder joint failure. This article focuses on two typical BGA solder joint failure modes: Cold Soldering and Grape Ball Effect.

The basic elements of cold soldering cover three pieces: excessive impurities in the solder joint, improper cleaning, and insufficient temperature.

What we normally call cold soldering refers to insufficient temperature, that is, insufficient heat due to certain factors during soldering, resulting in the solder not melting completely.

The actual production of the temperature is not enough to affect the cold welding factors

1. Insufficient thermal compensation performance of the equipment, temperature measurement at no load is qualified, the temperature at full load is insufficient resulting in cold soldering;

2. unqualified temperature measurement plate production, the difference between the test temperature and the actual production temperature;

3. no temperature measurement board, alternative temperature measurement board and the actual product heat capacity is different, the difference is large;

4. not using carriers when measuring temperature, the actual production has the use of carriers over the furnace resulting in large differences in temperature, as well as the use of carriers and the production of different heat capacity of the use of carriers resulting in temperature differences;

5. sudden failure of the equipment heater;

6. unqualified temperature curve setting, direct production without measuring the furnace temperature;

7. equipment alarm, the operator did not confirm the direct key resulting in equipment cooling;

8. Temperature curve program call error;

9. start to pass the plate without heating up;

10. Objects obscure the temperature, such as material tape and other foreign objects obscure.

Grape Ball Effect

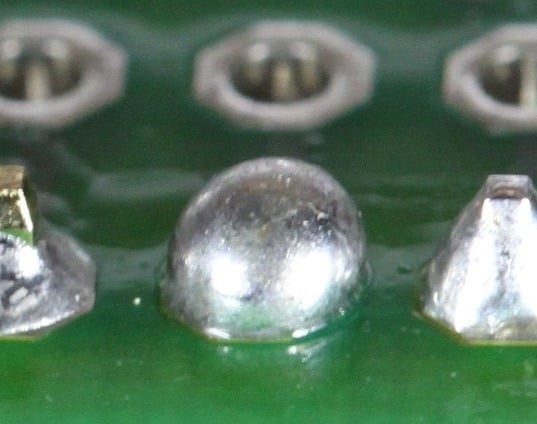

Another type of BGA solder joint failure mode is called the "grape ball effect".

The mechanism of the grape ball effect is that the solder paste flux loss is too much to remove the oxide film on the surface of the solder end and the oxide film on the surface of the solder paste powder particles, and the solder powder melts but cannot be fused and becomes granular after cooling.

The grape ball effect is often generated by PCBA process personnel copying the recommended temperature curve of the solder paste manufacturer, without paying attention to the temperature start and end point of the thermostat zone and the total time between the starting point of the thermostat zone and the melting temperature of the solder.

Coping strategies

In order to prevent and avoid the occurrence of cold soldering and the grape ball effect, improvements need to be made in the following areas:

1. Use longer-life solder paste to reduce the possibility of moisture oxidation and flux volatilization of solder paste.

2. Properly shorten the reflow curve in the constant temperature time to avoid excessive flux volatilization. However, the constant temperature time should not be too short, otherwise it will lead to uneven melting of the solder paste, affecting the quality and reliability of the solder. In general, the constant temperature time should be controlled between 60 to 120s to achieve the best results.

3. Use nitrogen protection to reduce the rate of solder paste oxidation.

Back to list

Back to list