T8~T10 Ultra-Fine Solder Powder Helps Micro-Gap Chip Packaging_Shenzhen Fitech

T8~T10 Ultra-Fine Solder Powder Helps Micro-Gap Chip Packaging

Solder powder is a kind of connection material used in the electronic industry, mainly composed of Sn and other metal (such as Pb, Ag, Cu, etc.) alloy powder. Solder powder can be used to prepare solder paste, which is used for soldering electronic components in surface mount technology (SMT). The quality requirements of solder powder include chemical composition, morphology, particle size distribution, oxygen content, etc.

Solder powder can be divided into conventional solder powder (T6 and below) and ultra-fine solder powder (T6-T10) according to the particle size. At present, the mainstream preparation methods of conventional solder powder are centrifugal atomization and ultrasonic atomization. However, these two methods have some problems and limitations when preparing ultra-fine solder powder above T6.

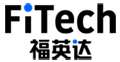

Figure 1. Conventional solder powder preparation process.

The centrifugal atomization method has mature technology, large output, and wide particle size range of the obtained solder powder, from Type3, Type4 to Type5, Type6 solder powder, there are certain production ratios. But when used to prepare ultra-fine powder above T6, it will face the following problems:

1. The size is difficult to control, the particle size is dispersed, it is difficult to analyze accurately, the quality is unstable, and the application performance is affected;

2. The oxygen content is difficult to control, which affects the wettability and solderability of the solder;

3. The sphericity is poor, the surface of the alloy powder is damaged, which is easy to cause oxidation, flux corrosion, resulting in poor rheological properties, poor reproducibility, and poor reliability of the solder paste.

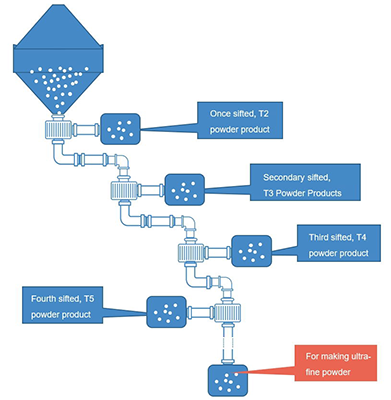

The solder powder prepared by the ultrasonic atomization method has excellent quality, such as good sphericity, low oxygen content, etc. It is the mainstream powder manufacture process in European countries. But when used to prepare ultra-fine powder above T6, there are the following pain points:

1. The equipment cost of ultrasonic atomization is high, and the quality requirements of raw material tin ingots are high, the powder manufacture efficiency is low, and it is not suitable for large-scale production;

2. The yield of ultra-fine powder above T6 is low, and it is difficult to meet the large demand of solder powder above T6;

Figure 2. Morphology (SEM) of solder powder prepared by ultrasonic atomization and conventional centrifugal atomization.

With the development of microelectronics and semiconductor packaging technology, the chip pad size and spacing are getting smaller and smaller, the accuracy and density of the pads are constantly increasing, and the difficulty and requirements of soldering are constantly increasing. For example, the smallest components on mobile phones and watches are now 01005, 0.35pitch, and continue to develop in the direction of more micro, finer, and denser. The next generation product is 008004, which is metric 0201, 03015 is just a transition product. The 0.35pitch pad is only 0.2mm, and there is a bare chip mounting requirement of 0.15pitch, and the bump pad is only 0.08mm. These ultra-micro-gap chips pose a huge challenge to soldering. Therefore, in addition to meeting the packaging requirements of conventional chip sizes, solder paste must also be suitable for more and more miniaturized packaging scenarios.

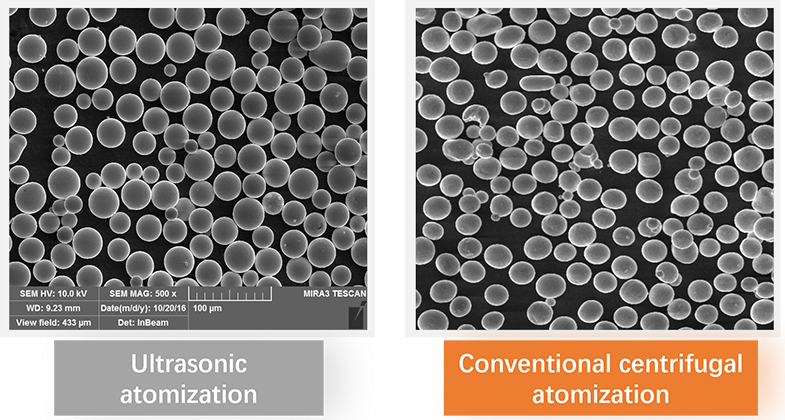

In order to adapt to the chip packaging needs of smaller gaps, Shenzhen Fitech launched T8~T10 ultra-fine solder powder. The solder powder adopts Fitech’s patented powder manufacture technology-liquid molding technology, which uses the principle of ultrasonic cavitation effect, which can be used for T6 (5~15μm) and above ultra-fine solder powder preparation, and has been mass-produced (hourly output up to 40kg, annual output up to 160t).

The T8~T10 ultra-fine solder powder products prepared by liquid molding technology have the following advantages:

1. Mass production of various types and sizes of ultra-fine solder powder, T7 (2-11μm), T8 (2-8μm), T9 (1-5μm) and T10 (1-3μm);

2. The particle size of the alloy solder powder can be controlled, and the particle size distribution is highly concentrated;

3. The sphericity is as high as 100%, the solder drop is smoother, and the stability of the printing and dispensing performance is ensured.

4. The surface of the solder powder is coated with technology, the oxygen content is low, and it has excellent reliability;

5. Various alloy types, low temperature (melting point temperature 139°C) & medium and high temperature (219~245°C) ultra-fine solder powder can be prepared.

Figure 3. Morphology (SEM) of ultra-fine solder powder prepared by Fitech’s liquid molding technology.

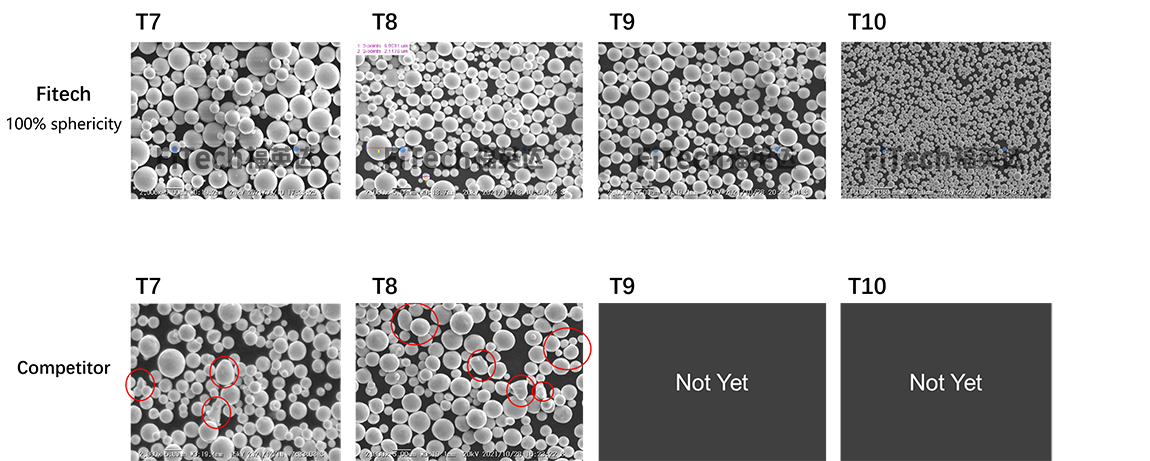

Figure 4. Comparison of the morphology of ultra-fine solder powder between Shenzhen Fitech and international comperitor.

It can be seen that Fitech’s T8~T10 ultra-fine solder powder has obvious advantages in particle size, morphology, and performance, and can meet the high requirements of micro-gap chip packaging.

Fitech’s T8~T10 ultra-fine solder powder has been widely used in SMT, die bond, micro bump, narrow gap, dispensing, jet printing, laser soldering and other solder paste products. With the development of microelectronics and semiconductor packaging technology, its application fields are also more and more extensive. At present, it has been rapidly developed in micro-optoelectronic display, automotive electronics, Internet of Things, mobile communication and other consumer electronics, SiP system-level packaging and other fields, and has received unanimous praise from industry users, and has been widely recognized by global SMT electronic chemical manufacturers, micro-optoelectronic manufacturers and semiconductor packaging and testing merchants.

About Fitech

Fitech is a professional custom, R&D, production and sales of alloy solder powder material solutions provider, a national high-tech enterprise, the leading unit of the Ministry of Industry and Information Technology’s electronic industry solder powder standard, Shenzhen “specialized, refined, special and new” enterprise and national specialized, refined, special and new “little giant” enterprise, has been focusing on the alloy solder powder material industry since 1997. Fitech has a complete product line of SMT alloy solder powder, ultra-fine solder powder, gold-tin solder powder, indium-tin solder powder, low alpha solder series. It is currently the only electronic packaging material manufacturer in the world that can manufacture T2 -T10 full-size alloy solder powder. The company has obtained ISO9001 management system, ISO14001, QC080000 and IATF16949 certification. If you want to know more about T8~T10 ultra-fine solder powder products, please call for consultation.

Back to list

Back to list