Improve Package Reliability and Efficiency with Low- Temperature SnBi Epoxy Solder Paste_Shenzhen Fitech

Improve Package Reliability and Efficiency with Low-Temperature SnBi Epoxy Solder Paste

The use of low-temperature solder paste in the electronics industry is gaining attention, especially with the miniaturization of integrated circuit components and the increase in the number of I/Os. While the traditional lead-free SAC solder reflow process is commonly used, high temperatures tend to lead to reliability problems, including low process yields and poor thermal cycling performance, which are often associated with warpage.

Figure 1. Conventional SAC solder is prone to warpage due to high soldering temperatures.

Low-temperature solder paste can be effective in solving warpage problems, and the industry typically uses SnBi alloys to improve process yields, eliminate the pillow effect and improve rework yields. However, in most applications, SnBi alloys are often not strong enough to replace lead-free (SAC) and eutectic tin-lead alloys. To enhance the strength, mechanical properties and reliability of SnBi solder joints, an effective method is to use epoxy resin in SnBi alloy solders instead of rosin resin in solder pastes. The epoxy resin adhesive remains and cures after soldering, acting as a reinforcement of the solder joints, protection and reinforcement.

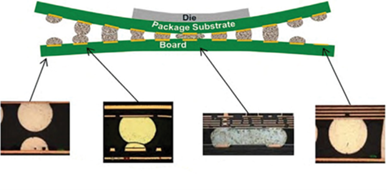

Epoxy solder paste (solder adhesive) the appearance and use of the process and solder paste is basically the same, it is also through the printing process such as dispensing in the pad sizing, and then in the patch alignment after heating and welding. In the heating process, the alloy powder first melting contraction, and pads to form a metallurgical connection, followed by crosslinking reaction curing thermosetting adhesive, after cooling to complete the device package.

Figure 2. Comparison of epoxy solder paste and solder paste process.

The epoxy solder paste solution simplifies the encapsulation process by eliminating the need for cleaning and filler gels after soldering, thus saving encapsulation process time and cost. The program is very suitable for high-density micro-fine pitch, the formation of micro-bumps, effectively solving the limit of stencil open printing and huge transfer problems. It is also very suitable for device encapsulation applications that require high mechanical reliability.

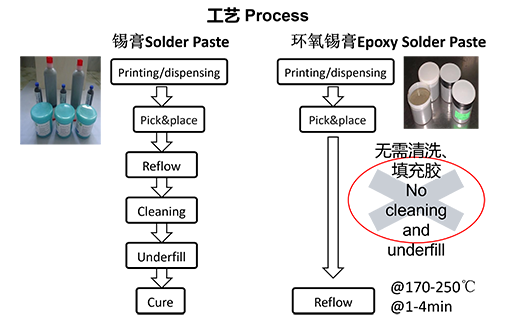

Epoxy solder paste solder shear strength (compared with solder paste) in Figure 3 shows that the cured strength of epoxy solder paste after soldering not only includes metallurgical connection force, but also increases the adhesive force of the hot-setting adhesive. Under the same alloy conditions, the shear strength of epoxy solder paste can be increased by 20~40% relative to solder paste, especially in the connection of tiny devices, this enhancement is more significant. This effectively solves the problem of brittleness of low temperature alloy solder pastes and solder "gold eating" (solder erosion off the plating).

Fig. 3. Soldering shear strength of epoxy solder paste (solder adhesive) (vs. solder paste).

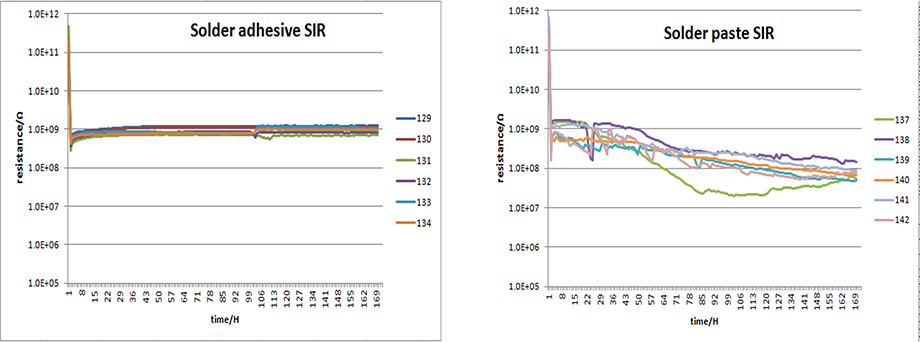

Fig. 4 Epoxy solder paste surface insulation resistance (vs. solder paste), according to JIS Z3197-2012 standard, epoxy solder paste performs better in terms of surface insulation resistance compared to solder paste after 168 hours of testing at 85°C 85%RH and 50V. This further confirms the superior performance of epoxy solder paste in electronic device applications.

Fig. 4. Epoxy solder paste surface insulation resistance (vs. solder paste)JIS Z3197-2012:85℃ 85%RH,50V,@168H.

In short, through the use of low-temperature SnBi epoxy solder paste, not only can improve the reliability and efficiency of the soldering process, but also be able to adapt to more and more miniaturized electronic components and higher requirements for mechanical properties, for the further development of the electronics industry provides a reliable solution.

Shenzhen Fitech self-developed epoxy solder paste products include low-temperature ultra-fine epoxy solder paste, medium and high temperature ultra-fine epoxy solder paste, Mini LED special ultra-fine epoxy solder paste and anisotropic conductive adhesive, welcome to call us for advice.

Back to list

Back to list