The Failure Modes of Solder Joints (1)

The Failure Modes of Solder Joints (1)

The rapid development of the semiconductor industry has put forward higher requirements for packaging solders. Once the solder joints massively fail after soldering, it will cause large-scale economic losses. After reflow soldering, various factors will cause the solder joint failure. This article focuses on grain boundary sliding, which is one of the solder joint failure modes. Before starting, it is necessary to understand what grains and grain boundaries are. The formation of grains occurs during the cooling (crystallization) process of many materials. A very important characteristic of metals is the average size of the grains. The size of the grains determines the properties of the metal. Grain boundary refers to the outer area of a grain that separates it from other grains. Grain boundaries separate differently oriented crystalline regions (polycrystalline) with the same crystal structure, preventing the dislocation diffusion. The small grains can enhance the mechanical strength.

Grain Boundary Sliding Explanation

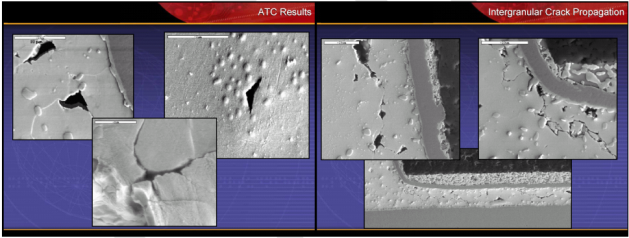

Grain boundary sliding is a mutual movement of grains due to shear displacement of grain boundaries or lattice regions adjacent to grain boundaries at high temperature, which can be regarded as a deformation mechanism in the creep process. Grain boundary sliding generates stress at the boundary and causes a wedge-shaped crack. As shown in Figure 1, the chip resistors assembled using Sn3.8Ag0.7Cu solder were subjected to aging and accelerated thermal cycling (ATC). In the early stages of thermomechanical fatigue, porosity and wedge-shaped microcracks preferentially occur at grain boundaries and at the matrix/intermetallic interface (Zbrzeznya et al., 2004). They only appear in the high-stress areas of solder joints. As the cyclic deformation progresses, these small cracks are eventually connected by intergranular cracks.

Figure 1: The ATC results of solder grains and intergranular crack propagation

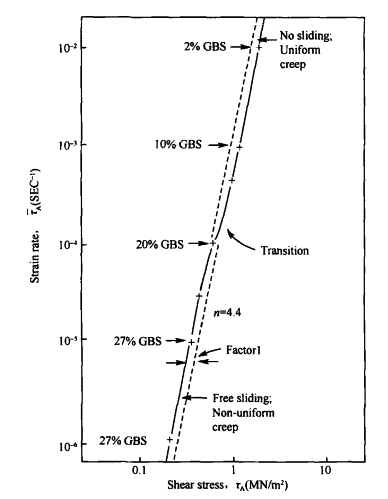

The figure below is a shear stress/strain rate graph showing the effects of grain boundary sliding on grain deformation. It can be found that when the shear stress is small, the grain boundary slip values are large. After passing the transition zone, grain boundary slip decreases rapidly with increasing shear stress (Zhang, 2010). Therefore, it can be obtained that the degree of grain boundary sliding is inversely proportional to the shear stress.

Figure 2: Shear stress/strain rate graph showing the effects of grain boundary sliding on grain deformation

With the long-term operation of solder joints, the fatigue degree gradually increases. Under the interaction of solder joint fatigue and creep, the reliability of SAC solder joints decreases, which may lead to failure.

Reference

Zbrzeznya, A.R., Snugovskya, P., & Perovicb, D.D. (2004), “Reliability of Lead-Free Chip Resistor Solder Joints Assembled on Boards with Different Finishes Using Different Reflow Cooling Rates”, IPC/JEDEC 5th International Conference on Lead Free Electronic Components and Assemblies.

Back to list

Back to list