The Failure Modes of Solder Joints (2)

The Failure Modes of Solder Joints (2)

During thermal cycling tests, solder joint microstructure coarsening and grain orientation are the important factors causing solder joint failure. This article focuses on the effects of solder grain size and orientation on the thermomechanical response and reliability of lead-free solder joints.

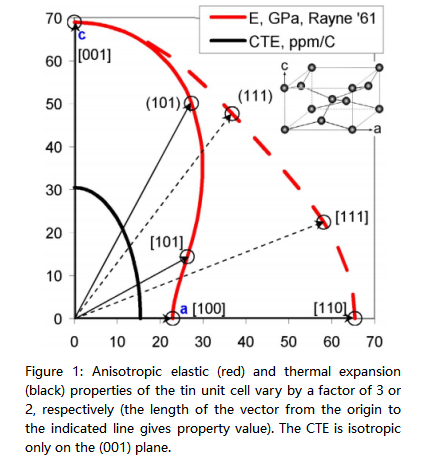

Different grain orientations affect metal elasticity and thermal expansion coefficients. As shown in Figure 1, Bieler et al. (2006) found that Sn grains have anisotropic elasticity in the c-axis nearly three times larger than in the a-axis. The thermal expansion coefficient in the c-axis is nearly twice that of the a-axis.

When the c-axis is parallel to the pads, there is a difference in the thermal expansion coefficients of the lead-free solder and the substrate. Due to the highly mismatched thermal expansion coefficients and high modulus, it is easy to form large stresses at the corners of the solder joints and cause local recrystallization, resulting in solder joint cracks. In addition, in a thermal cycling electronic system, stresses much higher than the yield force can lead to two adjacent, misoriented crystals (Bieler et al., 2006). A solder joint may contain only one grain. The anisotropic nature of grain orientation can cause uneven stress distribution between solder joints. As a result, the small solder joints are susceptible to shock.

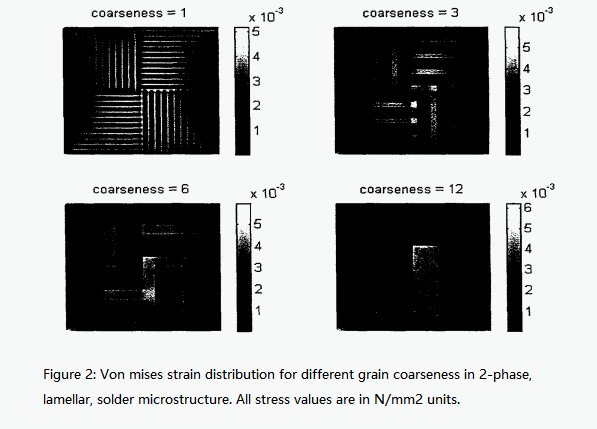

The solder is a material with high surface energy. When thermally and mechanically stressed, the solder joint absorbs energy, accelerating the atom diffusion and the growth or nucleation of grains. As the grain size enlarges, the solder joint voids will increase. Therefore, the grain size has a significant effect on the ductility and creep of solder joints. Chanchani (1999) simulated the lamellar microstructure of SnPb alloys and found that the maximum stress and strain values increased with grain coarsening (Figure. 2). If the stress increases beyond the yield stress, the solder joints will suffer a plastic deformation that affects the degree of joint fatigue. For two-phase alloys such as SnPb solder, since Pb does not form intermetallics with the substrate, Pb recrystallizes and generates large grains under the impact of thermal stress.

Dopants additions such as Ti and Ni into the solder may inhibit the growth of grains and play a role in refining the grains.

Reference

Bieler, T.R., Jiang, H., Lehman, L. P., Kirkpatrick, T., & Cotts, E.J. (2006), " Influence of Sn Grain Size and Orientation on the Thermomechanical Response and Reliability of Pb-free Solder Joints", Electronic Components and Technology Conference, 56th, pp.370-381.

Chanchani, R. (1999), “Modeling and Simulation - The Effects of Grain Coarsening on Local Stresses and Strains in Solder Microstructure”.

Back to list

Back to list