The Failure Modes of Solder Joints (3)

The Failure Modes of Solder Joints (3)

Due to legal and environmental protection requirements, it is imperative to replace leaded solder paste with lead-free solder paste. However, this process cannot realize instantly. After all, the development of different technologies is not completely synchronized. Therefore, it may be necessary to use both leaded and lead-free solder pastes for packaging in some current soldering scenarios. The presence of lead can harm solder joint reliability. This article mainly introduces the influences of lead contamination on soldering performance.

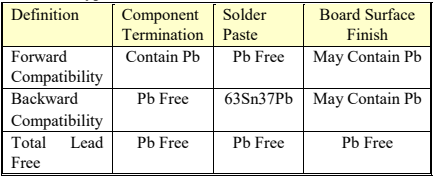

Mixing usage of leaded and lead-free solders has a potential impact on solder joint reliability. For example, backward compatibility occurs when lead-free solder paste is used in combination with leaded solder paste. The melting point of Sn63Pb37 solder paste is lower than that of SAC alloy. As a result, Sn63Pb37 solder paste on the pads will melt first, but the SAC solder balls will not melt if the reflow temperature is low. The melted Pb diffuses along the grain boundaries of the SAC solder balls, resulting in unstable solder joints that are prone to failure. Therefore, it is necessary to adjust the reflow profiles to match the solder melting point, reflow time, cooling time, etc.

Figure 1:Mixed-solder applications.

The Impacts of Lead Contaminent

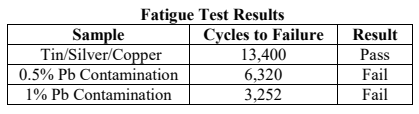

Seelig and Suraski (2001) added Pb to Sn95.5Ag4Cu0.5 solder paste for soldering and fatigue testing. It was found that increasing the Pb content reduces the fatigue resistance of the solder joints, representing that the solder joints fail faster (Figure 2). Key Chung et al. also conducted an experimental study on the effects of lead contamination, deliberately adding Pb to the lead-free solder Sn95Ag4.5Cu0.5 to produce a metal ratio of 97wt% of SnAgCu solder paste and 3wt% of Pb. DSC results showed that Pb reacted with Sn/Ag at the interface of Sn/Ag to form Sn62Pb36Ag2 ternary structure at 179℃, followed by Kirkendall void formation. The growth of Sn62Pb36Ag2 mainly occurs in the cooling stage and is inversely proportional to the cooling rate.

Figure 2: The results of solder joint fatigue test.

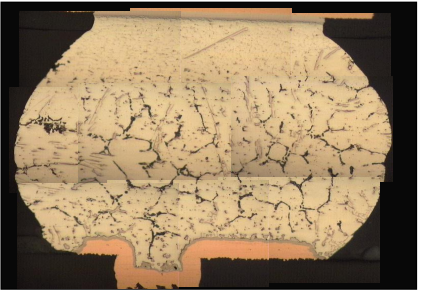

For backward compatibility, when the peak reflow temperature is lower than the melting point of the SAC alloy, Pb diffuses along the SAC solder paste grain boundaries, which results in grain coarsening of the lead-free solder balls (as shown in Figure 3). Furthermore, since the reflow temperature is lower than the melting point of the solder balls, the solder balls cannot melt effectively, producing an abnormal shape (Key Chung et al., 2002). As a result, the solder joints have low reliability and are prone to fatigue and failure during thermal cycling.

Figure 3: Pb diffuses along the solder paste grain boundary when then reflow temperature is lower than lead-free solder ball melting point. Black/gray - Pb rich area, rod shape - Ag3Sn, gray particles - Cu6Sn5.

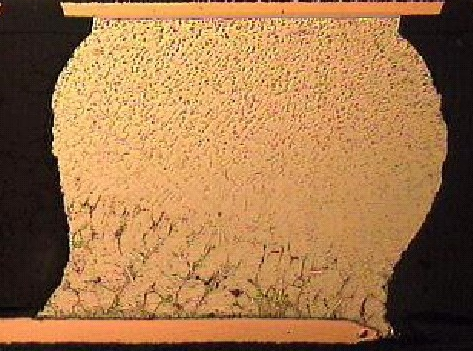

Figure 4: Solder ball was no completely collapsed after cooling, forming abnormal joint shape.

Regarding systems using a completely lead-free solder paste combination, sodler paste grain coarsening seems to be negligible, and the recrystallization process is mitigated. Therefore, the reliability of the solder joints will be higher than that of lead-contaminated soldering systems.

Shenzhen Fitech is a manufacturer specializing in the production and sales of packaging solder pastes. Fitech provides high-quality lead-free solder pastes for semiconductor packaging, such as tin-silver-copper solder pastes, tin-bismuth solder pastes, tin-antimony solder pastes, etc.

Reference

Key Chung, C., Aspandiar, R., Foo Leong, L., & Siew Tay, C. (2002), “The Interactions of Lead (Pb) in Lead Free Solder (Sn/Ag/Cu) System”, 52nd Electronic Components and Technology Conference.

Seelig, K., & Suraski, D. (2001), “Lead-Contamination in Lead-Free Electronics Assembly”.

Back to list

Back to list