Characteristics of Solder Paste: The Relationship between Solder Residue and Humidity

Characteristics of Solder Paste: The Relationship between Solder Residue and Humidity

Due to the influence of many factors, such as the design and manufacturing of electronic components and user needs, the reliability of electronic components in different application environments has attracted much attention. Flux is one of the essential components of lead-free solder pastes. The flux activator is typically made of acidic substances such as organic acid, which brings corrosion problems after soldering, affecting the reliability of components. Weak organic acids, such as carboxylic acids, are commonly used as activators. Carboxylic acids have polar functional groups, which make them have a high affinity for water. Most organic acids will be decomposed when exposed to high temperatures during reflow soldering, but a small amount remains under the PCBA components. During aging, it is easy to absorb water in the environment and generate corrosive substances. This article mainly analyzes the influence of environmental humidity on the formation of corrosive residues.

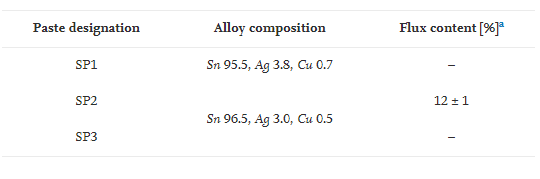

The hygroscopicity of weak organic acid residue of a lead-free solder paste makes it easy to form a thick acidic water film on the surface of PCBs when exposed to a humid environment. The water film has high conductivity, which significantly increases the probability of leakage current at the solder joints and leads to corrosion of the PCBs. In view of the influence of environmental humidity on the formation of corrosive residues, Piotrowska et al. (2021) conducted experiments using an acidity indication gel to observe the evolution of activators of solder pads after reflow soldering under different humidity (60% RH and 99% RH) and temperatures (25°C, 40°C, and 60°C). The characteristics of the testing solder paste are shown in Table 1.

Table 1. The characteristics of three experimental lead-free solder pastes (Piotrowska et al, 2021)

Experimental Results

As-reflowed

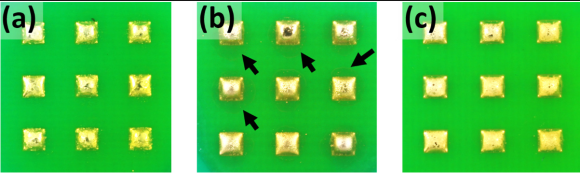

Due to the influence of many factors, such as the design and manufacture, acidity indication gel can react with acid and turn red. Therefore, it can be used to judge whether acidic corrosive substances are produced. Figure 1 shows the acid indication results of three lead-free solder pastes just after soldering. It can be observed that the acidity indication gel for SP2 had a slight color change (arrow direction). Since the soldering process had just been completed, the residues have not been fully developed.

Figure 1. As-reflowed acid indication. (a) SP1; (b) SP2; (c) SP3.

Effect of temperature at low humidity

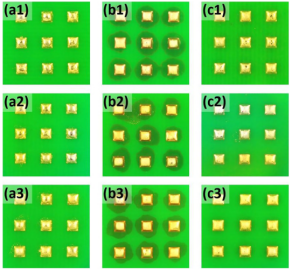

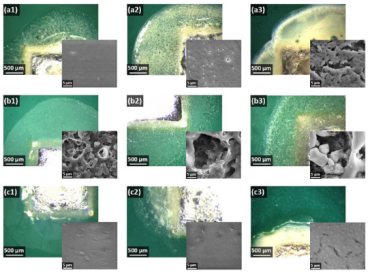

After 14 days of exposure, the red area of lead-free solder paste SP2 (b1-b3) can be viewed from the appearance. In addition, under the low humidity of 60%RH, the ambient temperature and exposure time did not have significant impacts on the number of residues around the solder joints.

Figure 2. Relationship between solder paste temperatures and residues when humidity is constant at 60% RH. (a) SP1; (b) SP2; (c) SP3. (1) 25℃; (2) 40°C; (3) 60°C.

Effect of temperature at high humidity

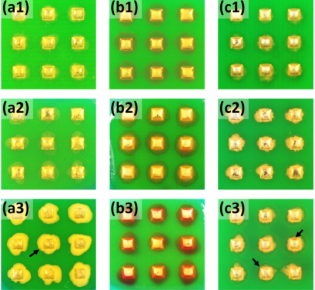

It can be seen from Figure 3 that after 14 days of exposure, the residues of all testing solder pastes are rapidly generated. It can be judged that humidity can accelerate the appearance of residues. Under high humidity conditions, the residue film cracked, and the acid evolved (Figure 4). Moreover, the high ambient temperature has an obvious effect on the evolution of residues. Higher temperatures will cause more visible residue film cracking.

Figure 3. Relationship between solder paste temperatures and residues when humidity is constant at 99% RH. (a) SP1; (b) SP2; (c) SP3. (1) 25℃; (2) 40°C; (3) 60°C.

Figure 4. Change of residue film when humidity is constant at 99% RH. (a) SP1; (b) SP2; (c) SP3. (1) 25℃; (2) 40 °C; (3) 60 °C.

Conclusion

In case of low humidity, the less corrosive residue is generated. On the contrary, there are more residues under high humidity. Therefore, a high humidity environment is the leading factor for the formation of corrosive residues. On this premise, the influence of temperature becomes more intuitive.

Reference

Piotrowska, K., Li, F. & Ambat, R. (2021), “Transformation of reflow solder flux residue under humid conditions”, Microelectronics Reliability, vol.(123).

Back to list

Back to list