SMT Component Placement _Fitech‘s SMD Solder Paste

SMT Component Placement _Fitech's SMD Solder Paste

After decades of development, surface mount technology (SMT) has become increasingly mature. It is well known that the number and density of components on an electronic device have increased dramatically compared with the past. If manual mounting is still massively used, the efficiency of assembling components on PCBs is slow, and the accuracy is compromised. Therefore, personnel in the industry developed SMT placement machines. The working efficiency of the placement machine is much faster than manual work. One placement machine can complete the assembly of tens of thousands of components per hour. It can be said that SMT placement machines have become essential equipment for SMT manufacturers.

Introduction of the SMT placement machines

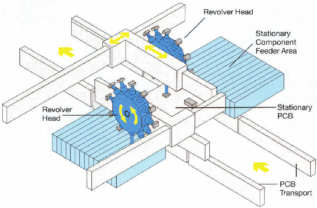

SMT placement machines have always been a hot topic in the industry. From the observation, mainstream manufacturers use the pick-and-place machine and collect-and-place machine. These two types of placement machines are very similar, but the placement heads are slightly different. The components are placed in the feeder. The placement head of the pick and place machine picks up a component and places it on a specific preset solder paste point. The collect and place placement head is equipped with multiple nozzles, which grab and place multiple components at specific solder paste points. The collect and place placement head collects the components through rotary motion and places them on the PCBs in sequence. The placement speed is more rapid, but there is also a greater possibility of position deviation.

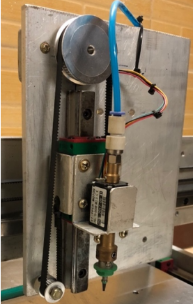

Figure 1. A simple pick and place mounting head structure.

Figure 2. Collect and place mounting structure.

The placement heads realize the function of the component collection by vacuum effect. The nozzle of the placement head is usually equipped with a laser beam or an optical camera, which can measure and align the position of the solder paste point. Finally, according to the set placement parameters (general category and size of components, PCB parameters, etc.), the mounting head rotates to place components.

Notes for SMT placement

The placement machine can pick up the components from storage places (such as paper tapes and plastic trays). It should be noted that the components should be kept away from static electricity. The component pickup is realized by vacuum nozzles, which have the advantage to avoid static electricity and ensure the current stability after soldering.

The nozzle performance needs to be monitored. When the nozzle cannot fulfill a newly completed placement cycle, it needs to be replaced. It takes a long time to change and adjust the nozzle after replacement. Therefore, frequent replacement is not recommended. In addition, components close to each other on the PCBs should be grouped together to minimize the movement distance of the placement heads.

Before SMD placement, it is necessary to ensure that sufficient solder paste is evenly printed on the pads. Since the assembly components are placed onto the deposited solder paste by the automatic placement machines, the height and width of the solder paste have impacts on the alignment of the nozzles of the placement machines. The improper solder paste volume and poor solder distribution uniformity can lead to misalignment of the placement head, which is easy to cause the tombstone problem. Besides, it is also important to select an appropriate printing solder paste formulation because the tackiness effect and the wettability of the solder paste after the placement are related to the solder paste formulations.

If you have any questions about the solder paste for SMT component soldering, please contact Fitech at any time. Fitech has rich experience in the production and application of solder paste, and its ultra-fine solder pastes (T6 and above) for ultra-fine-pitch soldering are leading in the industry. Fitech can provide SMT solder paste products and advises to help SMT manufacturers.

Back to list

Back to list