Types of Chip Scale Package (CSP) - Fitech Solder Paste

Types of Chip Scale Package (CSP) - Fitech Solder Paste

To realize the electrical paths of the integrated circuit chips, it is necessary to assemble the chips on a plastic or ceramic carrier, and this process can be called CSP. The size of the CSP is only slightly larger than the chip. The package size is usually not larger than 1.5 times the chip area or not greater than 1.2 times the chip width or length. The volume is several times smaller than that of QFP and BGA. Thus, it can achieve higher component mounting density on the PCBs. CSP also has a higher silicon ratio (ratio of silicon to package area) than QFP and PGA packages. The silicon ratio of QFP is about 10-60%, while the silicon ratio of a single chip of CSP is as high as 60-100%.

CSP is similar to other single-chip packaging forms, and the interconnection between the chip and the substrate is also realized through wire bonding and flip-chip bonding. The bonding of the chip to the substrate is realized by using an adhesive. The types of CSP include leadframe-based CSP, rigid substrate-based CSP, flex interposer-based CSP, and wafer-level CSP.

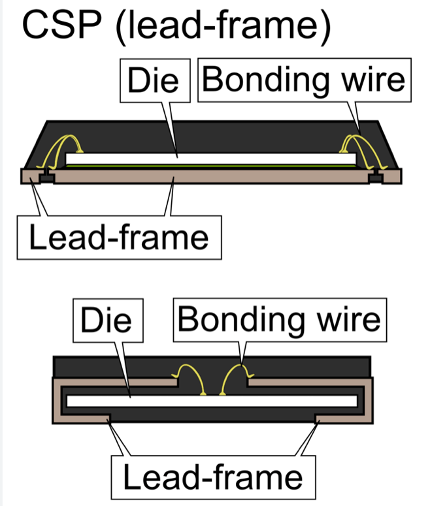

Leadframe-based CSP

Leadframe-based CSP is a common CSP type that enables leadless packaging. leadframe-based CSP requires the use of wire bonding techniques to connect the chip to the copper leadframe substrate. After the bonding is completed, the chip will be packaged in plastic to isolate external interference. The pads of the leadframe-based CSP are located on the outer edge of the package, and the assembly is achieved by attaching the exposed pads of the CSP component to the pre-coated solder paste of the PCB pads.

The leadframe-based CSP has many significant advantages over common plastic packages. The electrical performance is improved because the package size is close to the chip size, and the electrical path is further reduced. The absence of leads enables the component to be mounted by standard SMT equipment and soldered with solder paste, which saves more space on the PCBs.

Figure 1. Leadframe-based CSP structure.

Rigid substrate-based CSP and flex interposer-based CSP

Rigid substrate-based CSP uses ceramic or plastic laminates as the substrate material, such as bismaleimide triazine (BT). Flex interposer-based CSP is a market-leading technology in which the chip substrate is made of a flexible material, which can be a plastic film. Flex interposer-based CSP uses a flexible circuit with solder balls or metal bumps as an interposer between the chip and the next level of the PCB. Wire-bonded flexible substrate CSP is highly used in the memory industry. In addition, since the flexible substrate can provide more flexible wiring capabilities, it is very suitable for logic devices with high I/Os.

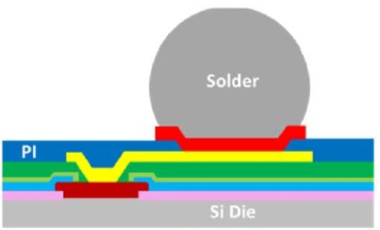

Wafer-level CSP

As the name suggests, wafer-level CSP can be understood as completing batch packaging directly at a piece of the wafer, which can reduce costs and increase production. In the manufacturing process of wafer-level CSP, it is required to redistribute the I/O pads, deposit the polymer film, prepare the UBM, and plant the solder ball to create the bumps. The bumped chips are then packaged and diced after testing is passed. The redistribution of pads is to meet the spacing and arrangement requirements of solder balls. A photolithography process similar to that used to manufacture ICs can be adopted in the redistribution of pads and preparation of bumps. Wafer-level CSP can be applied to many semiconductor devices, including power management, flash memory/EEPROM, integrated passive networks, and automotive electronics.

Figure 2. Wafer-level CSP structure.

Shenzhen Fitech can provide solder paste products for semiconductor soldering, which can be used for the flip-chip bonding of integrated circuit chips and surface mounting of components. In addition, metal bumps can be prepared by ultra-fine solder pastes instead of ball planting.

Back to list

Back to list