Effect of Solder Paste Particle Size Distribution on Roll-Offset Printing

Effect of Solder Paste Particle Size Distribution on Roll-Offset Printing

Traditional electronic component packaging uses stencil printing technology to deposit solder paste and other solder materials on the bonding pads. There is a rarely-used solder paste printing technology called roll-offset printing, which uses a roller to print solder paste to a specific position. The preparation of some electronic devices can be suitable for roll-offset printing applications, such as light-emitting devices, thin film transistors, solar cells, batteries, and sensors. The overall process of roll printing is shown in the figure below. It needs to roll and stick the solder paste on the solder paste with a roller and then make a small solder paste point of the same size as the bonding pads. Similar to stencil printing, roll-offset printing also needs to control the rheology of solder paste to ensure good printing quality.

Figure 1. Roll-offset printing process.

Roll-offset printing can realize the preparation of solder paste dots with small solder joint size and fine pitch with the advantage of low cost. Hence, it is considered an important means to produce the solder bump array with fine pitch. If solder bump arrays need to be prepared, rheology is a printing factor that must be considered. Son et al. studied the solder rheology by adjusting the particle size distribution of SAC305 solder paste. Son et al. produced several SAC305 solder paste samples with two solder size distributions in different proportions (0.5-2μm and 40-380nm). The rheological property and the particle interaction of prepared solder pastes were tested.

Table 1. Composition parameters of experimental solder paste.

Shear rate and viscosity change

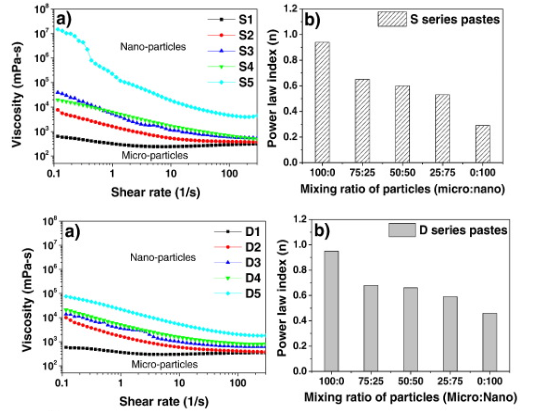

For the mixed micro and nano SAC305 solder paste (S series) with a small amount of dispersant, when the shear rate increased, the increase of nanoparticles in the solder paste led to a smaller power law index and larger viscosity change. Besides, the increase in the number of nanoparticles will occupy the original position of micron particles. Due to the stronger van der Waals force between nanoparticles, a large number of nanoparticles are easier to form aggregates, which is bound to affect the rheological properties.

Series D is a solder paste with more dispersant addition. Dispersants play an important role in inhibiting the accumulation of nanoparticles. Compared with the S series, viscosity changed more smoothly, and the power law index decreased slowly. In a word, the number of nanoparticles and aggregates has an obvious influence on the solder shear thinning effect.

Figure 2. Shear strength change of S series solder paste (upper) and D series solder paste (lower).

Aggregates of nanoparticles can exert more solid-like elastic properties, and if the surface area of nanoparticles is too large, there will be more interaction with flux components. The surface interaction between the nanoparticles and the flux may cause the solder paste flow to be blocked in response to the shear force, which makes the solder paste highly viscous. Therefore, the fluidity of the solder paste decreases. Son et al. believed that it would be more beneficial to improve the printing effect by controlling the power law index below 0.7 and reducing aggregates as much as possible. Son et al. used D2 SAC305 solder paste and successfully adopted roll-offset printing technology to prepare a solder bump array with a height of nearly 38 μm.

Shenzhen Fitech can provide customers with ultra-fine solder paste for flip-chip soldering of micro bumps. After reflow, the solder joint size is uniform, and the bump height is highly consistent.

Reference

Son, M,J., Kim, I.Y, yang, S.S., Lee, T.M & Lee H.J. (2016). “Employment of roll-offset printing for fabrication of solder bump arrays: Harnessing the rheological properties of lead-free solder pastes using particle size distribution”. Microelectronic Engineering, vol.164, pp.128-134.

Back to list

Back to list