The Squeegee System of Solder Paste Printing Process - Shenzhen Fitech

The Squeegee System of Solder Paste Printing Process - Shenzhen Fitech

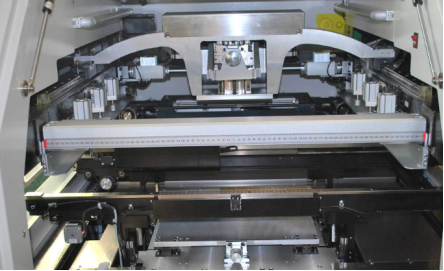

Solder paste printing is a process of coating solder paste onto the PCB pads. It is an important process of component assembly and plays a vital role in the soldering reliability of components. The main body of the solder paste printing machine is composed of a squeegee system and a stencil. The aperture structure of the stencil corresponds to the layout of the copper pads on the PCBs, and the solder paste is printed onto the pads through the stencil apertures. The stencil printing squeegee system is mainly composed of a printing head, a motor, a squeegee frame, a solder blocking plate, an automatic solder feeder, and a squeegee. It can be confirmed that the squeegee system significantly influences the solder paste printing quality.

Figure 1. Appearance of solder paste printer.

1. Introduction of the squeegee system

The printing head is the basis of the whole squeegee system, which controls the movement of the squeegee in the horizontal direction. The squeegee can be made of nickel stainless steel, spring stainless steel, ceramics, etc. According to the structure, squeegees can be divided into stepped and flat types. The squeegee length should be designed according to the size of the PCBs. The popular width of squeegee is 30mm, and some manufacturers adopt different sizes of 25mm, 40mm, etc. The price of a squeegee fluctuates dramatically. An ordinary squeegee costs tens of Chinese yuan, while better ones may cost more than a thousand Chinese yuan.

The squeegee is fixed on the squeegee frame that moves up and down to adjust the position. The printing process is completed by moving the squeegee to contact the stencil. The purpose of the automatic solder feeder on the printing machine is to automatically transfer the solder paste from the cans/syringes onto the stencil if the solder paste on the stencil is insufficient. The traditional solder-blocking plate is made of metals, and the solder blocking performance is relatively ineffective. Currently, the mainstream solder-blocking plate adopts a rubber structure, which can play an excellent role in preventing the solder paste from overflowing to both sides.

2. Impact of squeegee system on printing quality

2.1 Squeegee features

The width of the squeegee is a factor that affects the printing quality. The squeegee with an excessively large width will have greater flexibility, and it is easy to have inconsistent printing angles at each position of the squeegee when the printing pressure is applied. The ideal squeegee should have good rigidity, and the squeegee end needs to have the high elasticity to ensure a high solder paste printability. However, elasticity and rigidity cannot coexist. Therefore, manufacturers need to customize specific squeegee thickness, step width, and elastic width through material testing to achieve outstanding comprehensive properties. In addition, since the flux component of the printing solder paste contains acidic substances such as organic acid, the surface finishes of the squeegee should have excellent acid and alkali resistance, and the surface finishes can keep the low surface to prevent the solder paste from sticking to the scraper blade.

2.2 Squeegee assembly and Squeegee angle

The squeegee should be installed parallel to the conveyor track of the printing machine. If the installation position of the squeegee is nonparallel to the conveyor track, the solder paste will be stacked outside the printing zone, resulting in the waste of solder paste and poor printing quality. The selection of printing angle will affect the volume and shape of the solder paste on the pads. According to the actual operation, the dominant squeegee printing angles in the industry are 45°, 55°, and 60°. For surface mount devices, the ideal squeegee angle is 60°. For through-hole devices, the ideal squeegee angle is 45°. A smaller squeegee angle can increase the volume of solder paste in the plated holes.

Shenzhen Fitech has rich experience in the production and application of printing solder pastes. The Fitech’s ultra-fine printing solder paste (> T6) can meet the requirements of ultra-fine-pitch and high-density soldering. What’s more, Fitech’s technicians can provide customers with various solder printing solutions. Welcome to contact us.

Back to list

Back to list