The Introduction of Ultra-Fine Printing Solder Paste

The Introduction of Ultra-Fine Printing Solder Paste

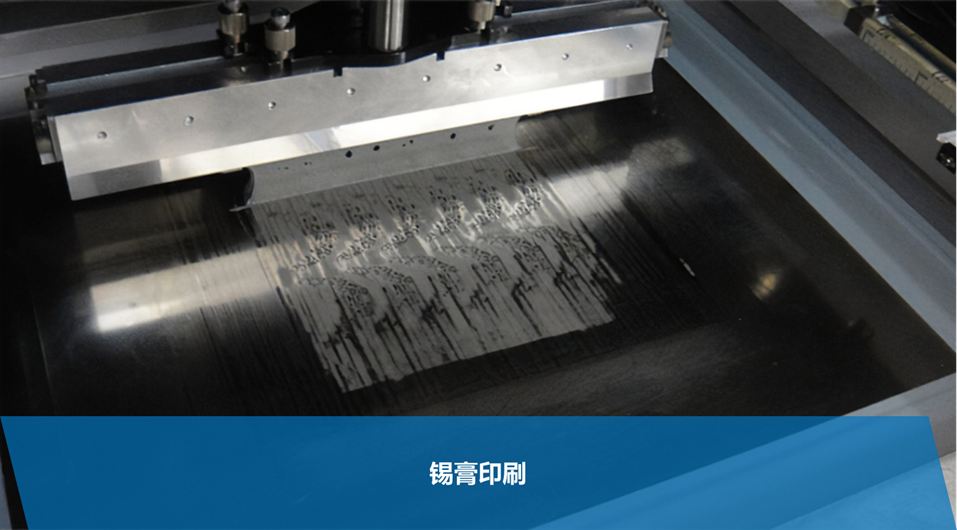

Definition of printing solder paste: Solder paste is printed on the substrate pads through the stencil opening. Printing solder paste is widely used in SMT and semiconductor packaging processes. It is the soldering material for the most popular electronic assembly process.

Key parameters of printing solder paste: Excellent printing solder paste requires outstanding mold release performance, long stencil online time, extraordinary anti-collapse performance, and superior thixotropic property.

Definition of ultra-fine printing solder paste: Ultra-fine printing solder paste refers to the printing solder paste products with particle sizes covering T6 to T10. With the continuous development of microelectronics and semiconductors, the chip size is getting smaller and smaller, and the packaging density significantly increases, such as in mini/micro LED display applications. Traditional solder paste products of T4 and above have been difficult to meet the requirements of microelectronics and semiconductor packaging. The solder paste products used in packaging are being ultra-micronized.

Fitech's T8 mLED 1370 low-Temperature Ultra-fine Printing Solder Paste for Mini LED

The differences between the ultra-fine printing solder paste and the traditional solder paste: The ultra-fine printing solder paste (T6 and above) has very small alloy powder particle sizes. The surface area of the ultra-fine alloy is great, leading to a higher contact area with the air. Therefore, it is more likely for the occurrence of oxidation.

It is embodied in the process of printing solder paste as follows: The solder paste with inappropriate oxygen control will be gradually oxidized by the oxygen during the printing process. The changes in viscosity and thixotropy cause an unstable process and worse reliability.

Quality control of ultra-fine printing solder paste: It is crucial to reasonable control of the oxygen content. Ensuring the process stability of printing solder paste is one of the keys to controlling the quality of ultra-fine solder paste.

-End-

Back to list

Back to list