PCB Solderability Test:_Tin Printing Experiment_Shenzhen Fitech

PCB Solderability Test:_Tin Printing Experiment

PCB tin test is to test the PCB solderability of a programme to assess whether the PCB pad can be good with the solder paste wetting and connection, which directly affects the SMT quality and reliability.

Printed tin experiment is to unpacked PCB bare board using the corresponding SMT steel plate normal printing paste, directly after the reflow to observe the effect of pad paste wetting to determine the performance of the PCB pad soldering. Even if there is no component mounted, the printed tin experiment can simulate the temperature change and chemical reaction in the SMT process, thus reflecting the quality and stability of the PCB surface treatment.

The advantages of printed tin experiment is:

It can verify whether the steel plate opening design is appropriate and whether the PCB surface treatment is good.

By comparing different types or batches of PCBs, potential problems or differences can be identified and timely improvement measures can be taken.

It can be used as a means of quickly screening or verifying PCB suppliers, improving procurement efficiency and quality assurance.

The disadvantages of the printed tin experiment are:

The process is more complex and requires preparation of steel plates and solder paste, as well as reflow equipment.

The cost of equipment and materials is high, and it takes up space and time.

The results are affected by a variety of factors, such as steel plate cleanliness, solder paste quality, reflow temperature profile, etc. Therefore, it is necessary to strictly control the process parameters and conduct sufficient data analysis and comparison.

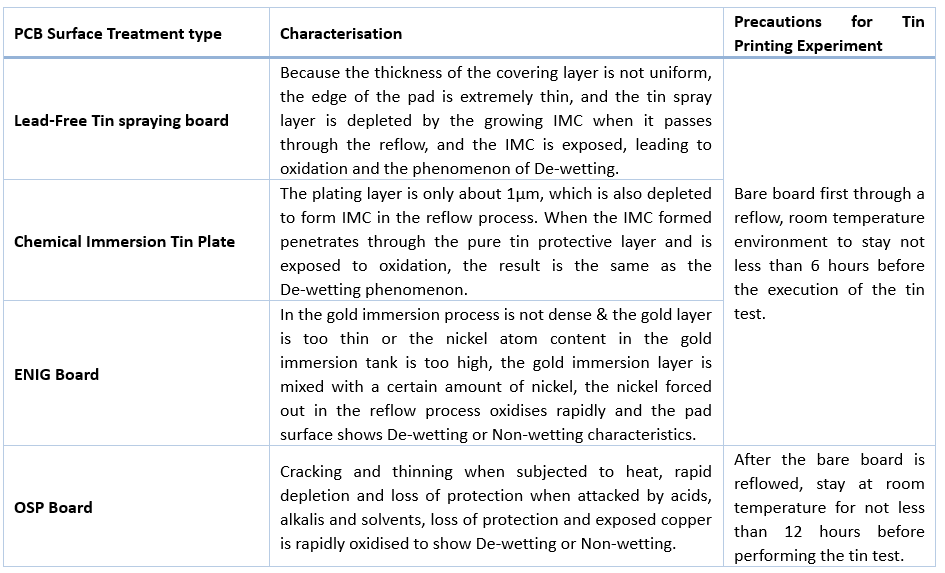

Different PCB surface treatment characteristics have different effects on the results of tin printing experiments. The following are several common PCB surface treatment types and their characteristics:

The conditions and results of the tin-on-tin test need to follow the relevant standards or specifications. The following are the general tin test conditions and results:

Experimental conditions:J-STD-003C-2014, IEC68-2-69, QJ831B-3.7.6.1/3.7.6.2; Newly opened PCB + normal production using reflow parameter settings + room temperature environment.

Experimental results:Solder paste melted area / solder paste printing area > 95%; solder paste wetting range shall not appear De-wetting or local refusal to solder, back wetting phenomenon.

Back to list

Back to list