Epoxy Flux on POP Laminated Packages_Shenzhen Fitech

Epoxy Flux on POP Laminated Packages_Shenzhen Fitech

For mobile devices such as mobile phones, area array packages such as BGAs, CSPs or POPs are prone to drop failures and need to be reinforced when they are assembled onto printed circuit boards. While underfill is an alternative solution, it increases manufacturing costs and reduces temperature cycling reliability due to the additional curing steps involved. As a result, an epoxy flux method is preferred, which eliminates the need for a curing step.

The epoxy flux is used as a flux when encapsulating the reflowed array onto the printed circuit board and then self-cures after reflow, providing the required reinforcement without the need for an additional curing step. Since pad collapse is a major failure mode in many portable devices, epoxy fluxes have become the preferred choice for cost-effective and reliable SMT assembly among all polymer-based reinforcement solutions.

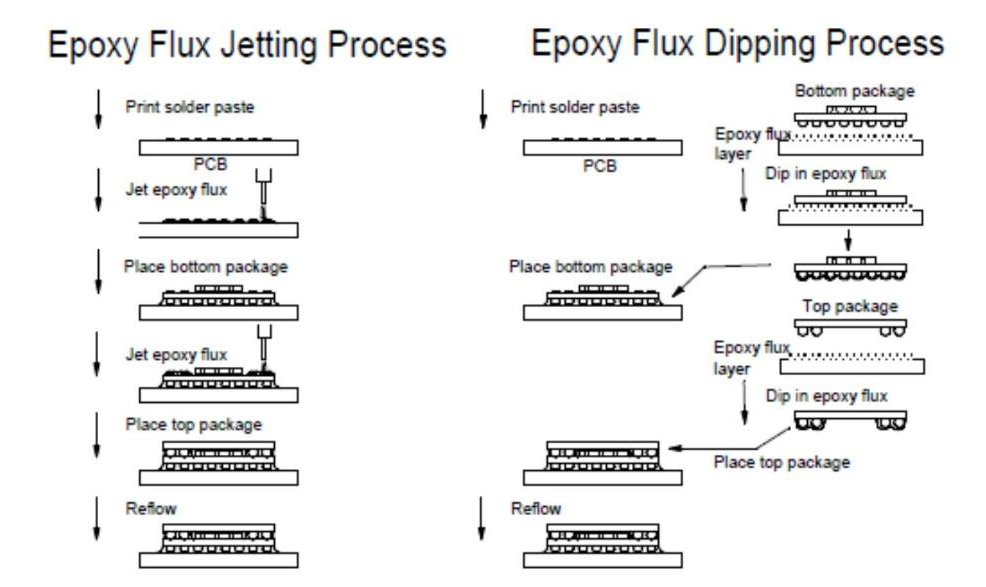

Figure 1. Epoxy Flux Spray and Dip Processes.

Epoxy fluxes are self-assembling and self-correcting. The epoxy cured after soldering provides insulation, corrosion protection and reliability enhancement, and it is compatible with underfill adhesives, bonding adhesives, etc., providing additional device protection and mechanical strength. The epoxy flux can be applied to the top components by dipping or printing, and then they are mounted onto the bottom components and reflow soldered.

Figure 2. POP laminated package.

1. High-precision positioning: it effectively prevents the top component from shifting and tilting in the placement process, ensuring the accurate positioning of components.

2. Reduce defects: epoxy flux effectively resist the warping and deformation of the top component in the process of reflow soldering, thus reducing the generation of defects such as false soldering, open circuit, ball and socket.

3. Improve connection strength and reliability: It enhances the connection strength and reliability between the top component and the bottom component, and enhances the performance of anti-shear, anti-stretch and anti-impact.

4. Component protection: epoxy flux effectively seal individual bumps to prevent moisture, dust, impurities and other intrusion, to extend the service life of components.

In short, the application of epoxy flux in POP laminated package has significant advantages, can improve product performance and quality, reduce manufacturing costs and risks. Epoxy flux is a new type of material system that deserves to be widely used in semiconductor packaging, printed circuit board assembly and even some emerging component processes such as stacked packages(POP).

The fine pitch flux produced by Shenzhen Fitech is suitable for high precision and high reliability packaging in the field of wafer bump welding, chip vapour plating welding, BGA, SiP, CSP, MicroLED packaging, module integrated circuits and so on. Welcome to call us for more information.

Back to list

Back to list