The effect of adding Cr on the performance of SnBi low-temperature solder alloy-Shenzhen Fitech

The effect of adding Cr on the performance of SnBi low-temperature solder alloy

With the development of electronic equipment towards miniaturisation, light weight and high density, the demand for low temperature solder is increasing. Low-temperature solder can reduce thermal stresses in electronic components, reduce thermal damage, improve productivity and save energy .SnBi alloy is a commonly used low-temperature solder, with the advantages of low melting temperature (139 ℃) and good creep resistance . However, the ductility of SnBi solder alloys is reduced by the brittleness caused by the Bi-rich phase and the formation of brittle IMC in the solder joints. These problems adversely affect the reliability of solder joints and will be magnified as electronic devices become increasingly miniaturised.

In order to improve the ductility and reliability of SnBi solder alloys, many researchers have attempted to add other elements to SnBi such as Ag, Cu, Zn, In, etc. Cr is a transition metal element that has attracted widespread attention due to its low cost and strengthening effect on solder.Zhu et al. added 0.1, 0.2, and 0.3 wt% Cr to SnBi alloys to study the effect of Cr on the composite solder joints. Cr to study the effect of Cr on the properties of composite SnBi solder.

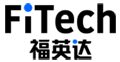

A large number of disintegrated surfaces can be detected in Fig. 1(a), which indicates that the fracture mechanism of pure SnBi solder is a brittle fracture mode. As shown in Fig. 1(b), the disintegration surfaces are almost completely disappeared and the grain profile is not as sharp as that in Fig. 1(a), so the brittleness of the solder is reduced. However, in Fig. 1(c) and (d), there are some tough nests representing ductile fracture modes in the SnBi-0.2Cr and SnBi-0.3Cr solder alloys. The results indicate that the fracture mechanism of solder alloys changes from brittle fracture to ductile fracture with the addition of Cr.

Figure 1. backscattered electron (BSE) microstructure images of (a) SnBi, (b) SnBi-0.1Cr, (c) SnBi-0.2Cr, and (d) SnBi-0.3Cr solders.

Fig. 2. Cr content in solder as a function of IMC thickness.

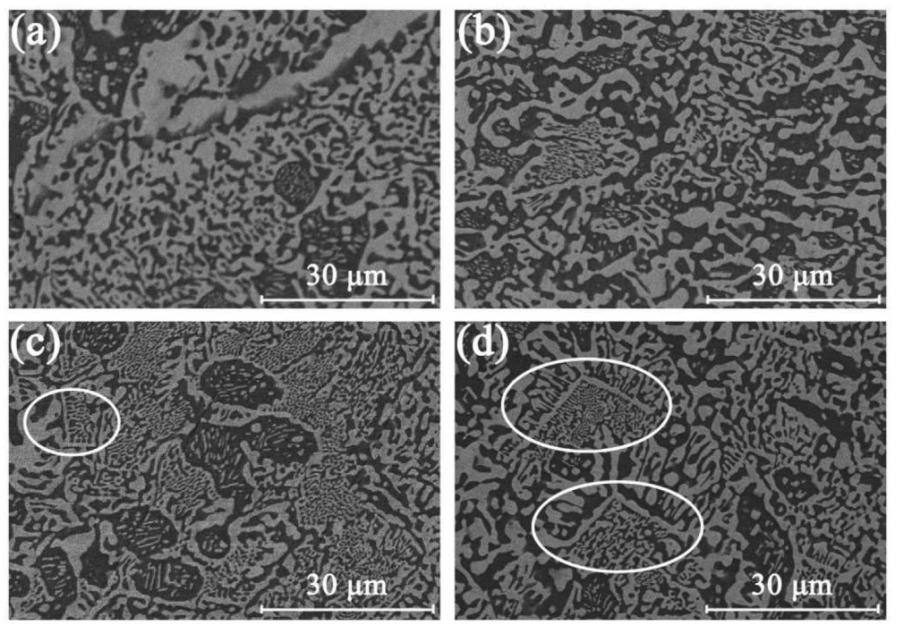

Tensile tests were conducted to evaluate the effect of Cr on the mechanical properties of the solder joints.The tensile strength of SnBi-xCr solder joints (x1/40, 0.1, 0.2, 0.3) is shown in Figure 3. As shown in the histogram of Fig. 3, the tensile strength of the welded joints increased significantly with the addition of Cr, whereas the tensile strength of SnBi-0.2 increased significantly.The Cr welded joints were 66 MPa, which was the highest value among all the tested samples. However, the trend of tensile strength of solder joints did not coincide with the trend of tensile strength of solder plates. The ultimate tensile strength of solder joints is affected by the thickness of IMC and solder.

Figure 3.Tensile strength of pure and composite solder joints.

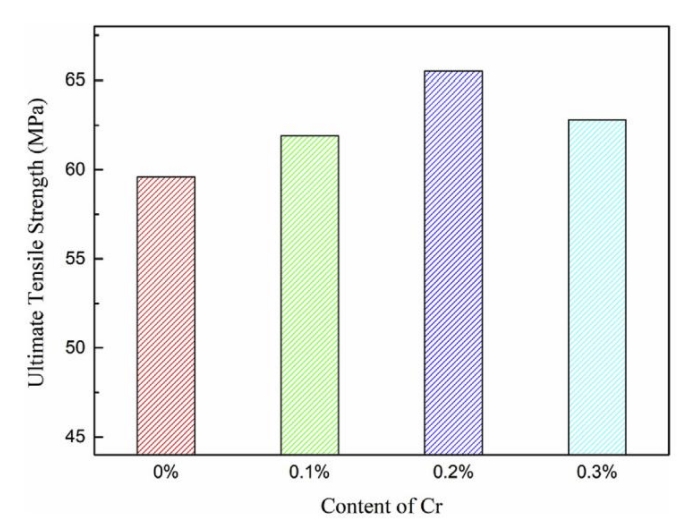

Fig. 4 depicts the creep depth of the pure and composite solder alloys. It can be seen that the creep properties of the monolithic composite solder have been enhanced to some extent after treatment. When the samples were subjected to a maximum force of 20 mN, the creep depths of 170.44 and 176.76 nm for SnBi-0.2Cr and SnBi-0.3Cr, respectively, achieved an effective reduction of 34% and 31% (~257.90 nm), respectively. The improved effect is attributed to the presence of Bi dendrite branches, which block dislocations and simultaneously enhance creep properties. On the other hand, the microstructure refinement also enhances the creep performance of the composite solder.

Fig. 4. Creep properties at 20 mN for different Cr contents.

The microstructure of the SnBi-0.2Cr solder is significantly refined compared to the pure SnBi solder. In addition, the formation of CrSn2 IMCs depletes the Sn phase and leads to the appearance of Bi rich dendritic branches.

The tensile strength showed an increase of 3% in the SnBi-0.1Cr solder sheet during tensile testing. However, the elongation of SnBi-0.2Cr and SnBi-0.3Cr solder sheets increased by 56% and 53%, respectively. In the tensile tests of the solder sheets, the addition of Cr resulted in a change from brittle to ductile fracture mode. The morphology of the Cu6Sn5 IMC layer in the composite solder joints changes from an elongated scallop shape to a continuous rough scallop shape, and the thickness of the Cu6Sn5 IMC layer decreases. As a result, the fracture path is shifted from part of the IMC layer to completely in the solder matrix, and the tensile properties of the solder joints are improved.The tensile strength of the SnBi-0.2Cr solder joints is increased by about 10% compared with that of the pure SnBi solder joints. The creep resistance of the composite solder is significantly enhanced.

Zhu, W., Zhang, W., Zhou, W., & Wu, P. (2019). Improved microstructure and mechanical properties for SnBi solder alloy by addition of Cr powders. Journal of Alloys and Compounds 789 (2019) 805-813.

Back to list

Back to list