Reduce Soft Error Rate of Microelectronic Packaging with Low Alpha Particle Solder Paste_Shenzhen Fitech

Reduce Soft Error Rate of Microelectronic Packaging with Low Alpha Particle Solder Paste

A soft error is a temporary failure of a device caused by the effects of radiation on silicon integrated circuits (Si ICs). Soft errors can affect the performance and reliability of devices, especially in high radiation environments such as space, defence, medical and power systems. As electronic devices continue to become more miniaturised and denser, the susceptibility to soft errors has increased, as even low-energy alpha particles can now flip a memory bit or alter the timing of a logic circuit. One major source of alpha particle radiation is the solder pastes used to connect components in packages, which contain alpha radioactive elements. Due to the use of flip-chip soldering and the development towards 3D packages, solder bumps have moved so close to active silicon devices that even low energy α-radiation can cause soft errors. Therefore, Low Alpha activity Pb-free solders need to be developed to reduce the occurrence of soft errors.

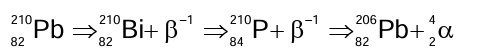

Lead-containing solder is thought to be a major source of alpha particles, as confirmed by a study conducted by the Microelectronics Centre of North Carolina (MCNC), which monitored alpha radiation at each step of the wafer bumping process. The radioactivity of lead can be traced back to 238 U. Starting from 238 U, it decays to 210 Pb, which further decays to Bi over a period of 22 years, then to Po, and then to 206 Pb over a period of 138 days. in addition to the alpha particles, the decay process involves the emission of beta particles (electrons). the beta particles have no effect on the soft error. The uranium content in natural lead sources varies by as much as three orders of magnitude. During smelting and chemical purification, although other elements may be removed, the radioactive 210Pb will concentrate with the non-radioactive 206Pb because the two lead isotopes are chemically identical. The alpha activity of lead can be as high as 100 α/(cm2 "h) within 8 to 9 months after smelting and purification.

The process of α particle production:

Chip manufacturers usually categorise the sources of alpha particles into intrinsic and extrinsic sources.

a) Intrinsic sources are those present in the processed silicon itself, but are usually less important. They are caused by process-related factors such as residues left by phosphoric acid etching. Phosphoric acid is commonly used for patterning silicon nitride insulating films during wafer fabrication; it is usually of relatively low purity and contains low levels of radioisotopes. Other intrinsic sources include trace impurities in the film oxides and nitrides, extraneous impurities added to the silicon during implantation operations, and impurities in the silicon wafer itself.

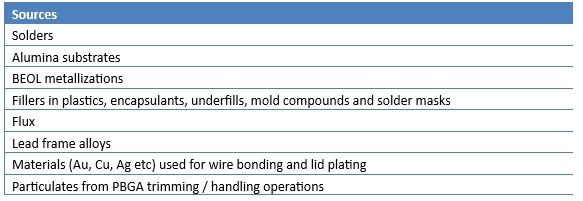

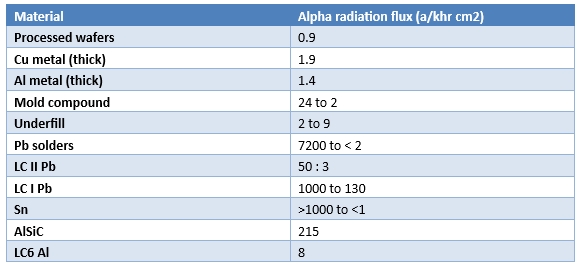

b) Extrinsic Sources: Extrinsic sources are usually different from the silicon chip, but within the integrated circuit package. Most alpha particle sources fall into this category. Table 1 lists the most common alpha particle sources in microelectronic packages. Individual contribution estimates for some of these α-particle emitting sources are listed in Table 2. It is currently believed that almost all materials used in integrated circuit packaging lead to soft error failures. The increasing sensitivity of devices to SERs due to shrinking size and proximity necessitates the development of routine monitoring procedures for incoming materials and manufacturing processes.

Table 1. Most common alpha particle sources in microelectronic packages

Table 2. α-radiation activity of some common materials used in microelectronic packaging

In order to reduce the alpha particle activity in solder paste, there are two main methods: the use of lead-free solder and the use of low alpha active lead solder. Lead-free solders are solders that contain no or very low levels of lead, and they are usually composed of elements such as tin, silver and copper. The advantage of lead-free solder is that it avoids the environmental and human hazards of lead and also eliminates the source of alpha particles in the solder paste.

Low alpha reactive lead solder is lead solder that has been specially treated to remove the radioactive 210Pb. This treatment usually consists of two steps: the use of high-purity raw materials, and the use of a vacuum or inert gas environment for melting and purification. This effectively reduces the alpha particle activity in the solder paste to below 0.01 alpha/(cm2 "h). The advantage of low α-activity lead solder is that it can maintain the excellent properties of lead solder, such as low melting point, low oxidisation, low creep, low intermetallic compound formation rate, etc., and also reduce the occurrence of soft errors.

Currently, low alpha activity lead-free solder pastes have been used in some high-end microelectronic packaging areas, such as space, defence, medical and power systems. These fields require very high reliability of the devices and cannot tolerate the occurrence of any soft errors. Therefore, the use of low alpha activity lead-free solder pastes can effectively improve the radiation resistance and safety of the devices.

Low-alpha solder series is a high-lead solder with low alpha particle count developed by Fitech for high-density and miniaturised packages such as SiP System-in-Package and Flip Chip Flip Chip. They are used in mobile communication (smart phones, tablets, wearable devices), Internet of Things (Wi-Fi, BLTE, UWB, LTE-M & NB-IoT, consumer, industrial), automotive (infotainment systems), high performance computing (computing, networking, artificial intelligence) and other fields.

Fitech's low alpha products include low alpha (<0.01 cph/cm2) and ultra low alpha (<0.002cph/cm2), lead-free and high-lead alloys, with particle sizes ranging from T3, T4, T5 to T6. The low alpha solder series has the advantages of good sphericality, narrow particle size distribution, low oxygen content, and chemical purity, which meets the requirements of alpha particle emission specifications. It meets the requirements of alpha particle emission specifications and can provide customised development services. Welcome to contact us.

Santosh Kumar, Shalu Agarwal and Jae Pil Jung (2013). Soft error issue and importance of low alpha solders for microelectronics packaging. Rev. Adv. Mater. Sci.34 185-202.

Back to list

Back to list