How to improve the mechanical reliability of SAC solder paste_Shenzhen Fitech

How to improve the mechanical reliability of SAC solder paste_Shenzhen Fitech

SAC series solder paste is a common medium-temperature solder in semiconductor packaging. This type of solder paste can be used for soldering work at relatively high temperatures, and the strength after soldering is considerable. However, as the thermal stress on the solder joint accumulates, there is a certain degree of deformation between the solder joint and the chip due to the difference in thermal expansion coefficient, and the fracture mode of the solder joint will change over time, leading to a decrease in strength and failure of the solder joint. Therefore, it is necessary to study how to improve the strength of the solder joint. To achieve higher solder joint strength, it is possible to add trace metals to the solder paste to enhance it.

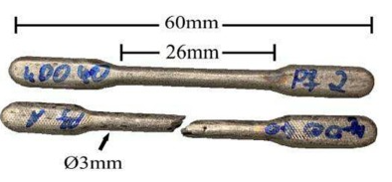

Steenmann, Richter, and Licht made tensile test samples from solder with micro-additives, where the solder was heated in the cavity of the copper substrate. The substrate cavity is ground and coated with TiCN to prevent copper diffusion. The gripping parts of the tensile specimen are approximately 15mm long, and 5mm wide, and the depth of the entire cavity is 3mm. The reduced part is 26mm long and 3mm wide. The peak soldering temperature covers 300°C, 350°C, and 400°C, while the holding time includes 10mins, 20mins, and 40mins. The test solder includes SnAg0.4Cu0.5 (SAC), SAC+Bi6 (Bi6), SAC+Ni0.2 (Ni02), and SAC+Sb3 (Sb3).

Figure 1. Solder samples used in tensile strength test.

The tensile test results

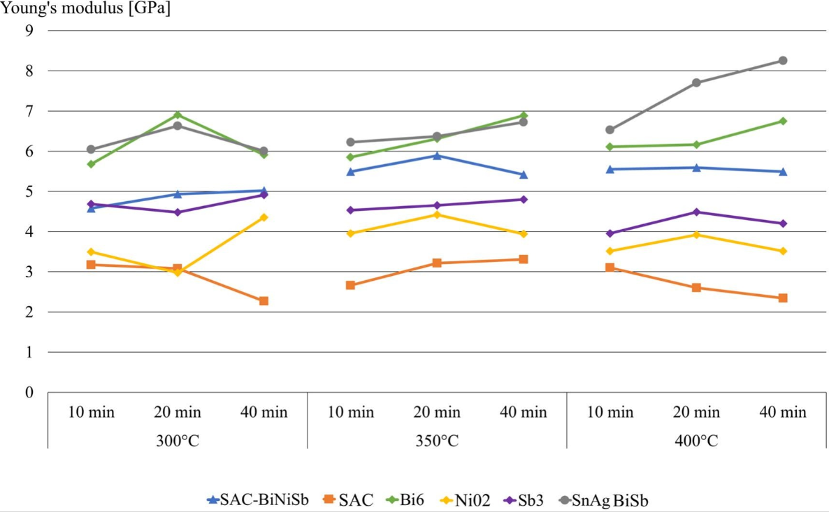

Figure 2 shows that Young's modulus of SAC solder is the smallest, indicating that SAC is more elastic and deforms faster than other solder materials. Compared with SAC, the Young's modulus of Ni02 (yellow) and Sb3 (purple) is higher, indicating that Ni and Sb have an increasing effect on the Young's modulus. In addition, a significant increase in Young's modulus and stiffness can be observed after adding 6wt% Bi (green) to SAC. It can be said that the addition of Bi helps to increase the Young's modulus. The Young's modulus of SAC-BiNiSb is generally higher than that of pure SAC solder, but lower than Bi6. SnAgBiSb is the hardest and therefore can withstand higher stresses without damage.

Figure 2. Young's modulus of different solder samples.

The maximum load-bearing capacity (Fmax) of the solder also reflects the reliability of welding. SAC solder without micro-additives has the smallest Fmax and is rarely affected by soldering temperature and holding time. For Ni02, as the soldering temperature and insulation time increase, Fmax slightly increases. If 6wt% Bi and 3wt% Sb are added to SAC respectively, the maximum tensile force is significantly improved, and the value of Bi6 is always higher. Although Bi is brittle, it can withstand higher stresses, so adding a small amount of Bi to SAC solder can improve its strength. In addition, as the soldering temperature increases, the Fmax of SAC-BiNiSb increases, while the Fmax of SnAgBiSb decreases.

Figure 3. Maximum force of different solder samples.

Fitech’s Solder Paste

Fitech is committed to producing a variety of high-quality solder paste products to meet customers' requirements for different soldering temperatures and joint strength. In addition, Fitech’s solder paste viscosity can be customized to meet customers' needs for printing and dispensing processes. Welcome to contact us for more product information.

Reference

Steenmann, A., Richter, J. & Licht, T. (2023). Micro-additives and their impact on tensile and fracture performance of solder. Microelectronics Reliability, vol.150.

Back to list

Back to list