Lead-Free Solder BGA Fatigue Performance _Shenzhen Fitech

Lead-Free Solder BGA Fatigue Performance _Shenzhen Fitech

Solder joint metal will gradually fatigue under stress and easily lead to a decrease in solder joint strength. In most cases, the size of solder joints used to study fatigue performance is relatively large. Only a few studies have examined the fatigue properties of BGA solder joints. Generally, the surface finish of solder pads and the metal composition of BGA will have varying degrees of impact on the fatigue performance of BGA solder joints. The common surface finish for solder pads on the market includes OSP, ENIG, etc. In addition, SAC305 type BGA solder alloy is widely used in the packaging industry due to its moderate melting point.

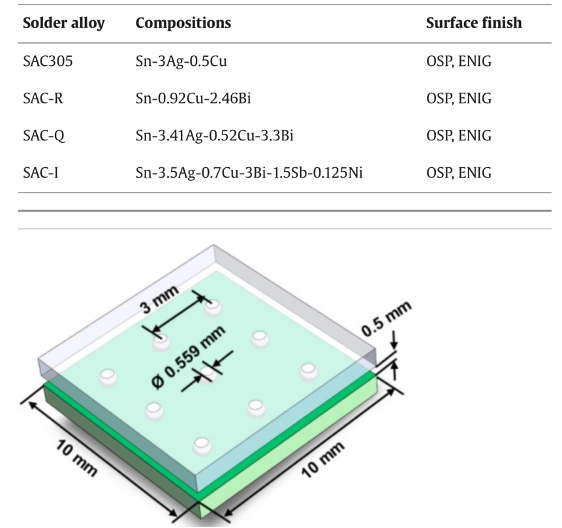

Adding some trace elements to SAC305 solder can enhance the solder. Bonding with different surface finishes often results in better fatigue performance. Wei et al. selected different BGA metal alloys and OSP and ENIG pads for room-temperature solder joint fatigue testing. Due to the high strength of SAC-Q and SAC-I, higher stresses were chosen for testing. The PCB board is refluxed in a nitrogen reflux furnace, with a peak temperature of 245°C. Characteristic life refers to the number of cycles required to achieve a failure probability of 63.2%.

Figure 1. Solder alloys and BGA structure.

Experimental results

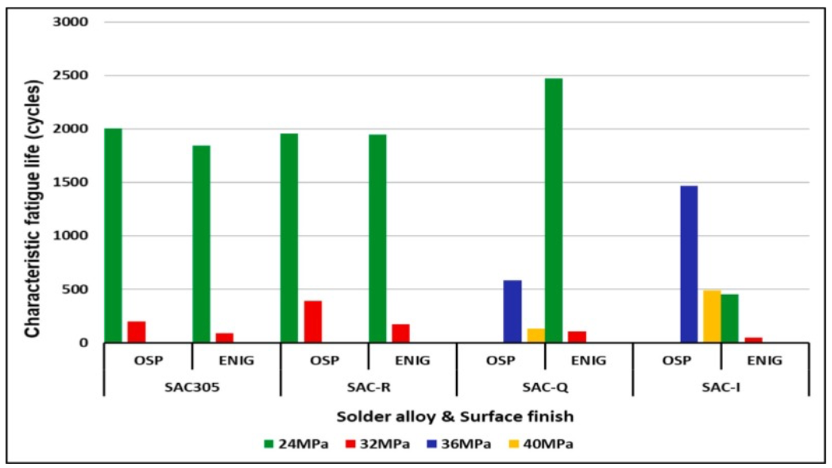

From the experimental results in Figure 2, it can be observed that regardless of the solder alloys and surface finish, the higher the stress level, the more damage accumulated in each cycle, and the shorter the fatigue life. SAC-Q and SAC-I perform better than SAC305 and SAC-R under the same OSP surface treatment, as they can still maintain a certain degree of fatigue life at higher stress levels (36MPa). At 40MPa, SAC305-I has the longest fatigue life. Regarding ENIG surface finish, there was no significant difference in fatigue life among SAC-Q, SAC305, and SAC-R at almost all stress levels. In addition, SAC305 solder joints outperform ENIG on the surface of OSP, especially at higher stress levels, which means that OSP can make the connection between solder joints and copper pads more secure.

Figure 2. Fatigue Life of Different Solders in Stress Testing.

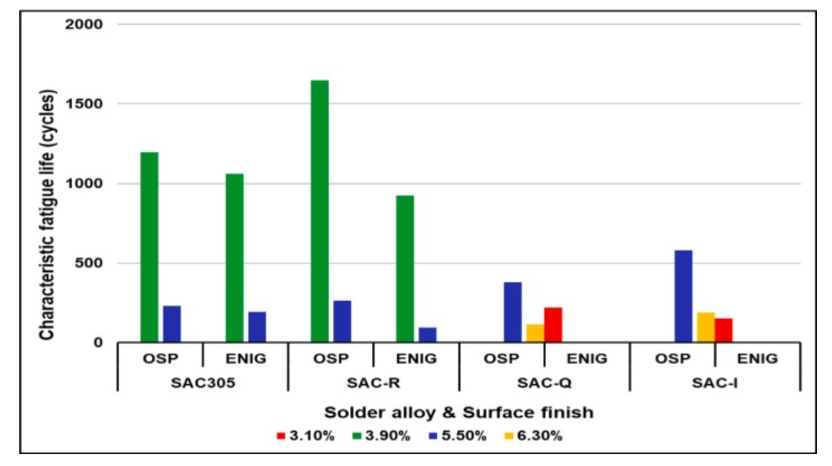

During fatigue testing, higher strain levels can lead to more cyclic damage, thereby shortening fatigue life. Under low and high strain levels, the fatigue performance of these SAC305 solder joints on OSP surface finish is superior to that of ENIG. Overall, the fatigue performance of SAC-R under stress testing is relatively close to that of SAC305. However, SAC-Bi solder joints with ENIG surface finish are very sensitive to brittleness issues and can easily lead to a shortened fatigue life. In addition, the Ni layer of ENIG hinders the diffusion of Cu, leading to the thinning of the IMC layer. An excessively thin IMC layer can weaken the reliability of solder joints.

Figure 3. The fatigue life of different solder alloys in strain test.

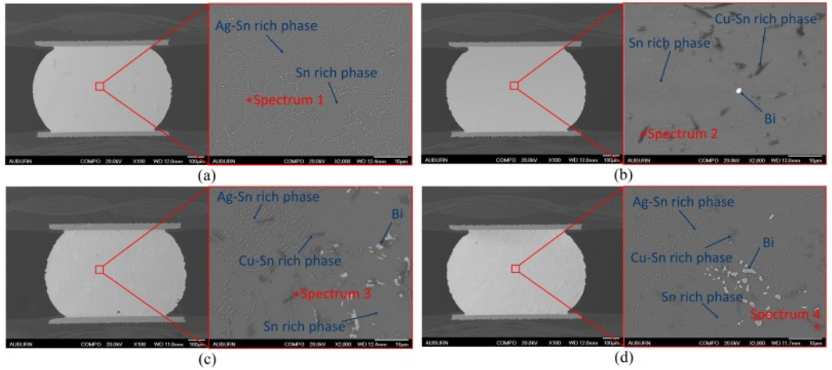

The morphology and distribution of the Ag3Sn phase in SAC305 solder joints also affect their reliability. Ag3Sn precipitates with finer microstructures and lower aspect ratios exhibit more robust mechanical properties. SAC-R has no Ag component but contains 2.46wt% Bi. Adding Bi to SAC-R solder joints can compensate for the lack of Ag3Sn precipitates, making their mechanical and fatigue properties closer to SAC305. However, due to the Bi content exceeding the solubility limit of Bi in the Sn matrix at room temperature, which is 2.3wt%, a small number of Bi separates and forms Bi precipitates. Although SAC-I has less Bi than SAC-Q, it contains more Ag and Cu. Adding Sb and Ni to SAC-I also improved its reliability.

Figure 4. Morphology of different solder alloys. (a) SAC305; (b) SAC-R; (c) SAC-Q; (d) SAC-I.

Reference

Wei, X., Hamasha, S., Alahmer, A., Belhadi, M.E.A. & Vyas, P.P. (2023). Fatigue performance and microstructure of lead-free solder joints in BGA assembly at room temperature. Microelectronics Reliability.

Back to list

Back to list