Is Cleaning Necessary When Using No-Clean Flux?_Shenzhen Fitech

Is Cleaning Necessary When Using No-Clean Flux?

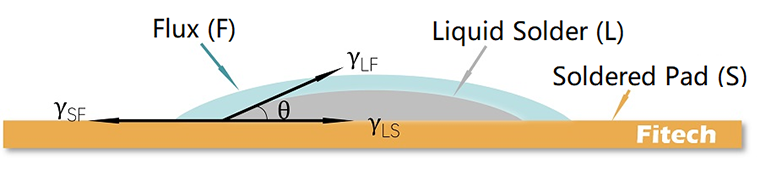

Flux is an indispensable substance in the soldering process, its role is to remove the oxides of the soldered parts, increase the wettability of the soldered joints, and improve the quality and reliability of soldering. Flux is divided into organic flux and inorganic flux, according to whether the need to clean, can be divided into washable flux and no-clean flux.

Figure 1. Mechanism of flux action

No-clean flux is a special type of flux that is characterized by the fact that it does not need to be cleaned with water or solvent after soldering and can be left directly on the circuit board. The advantage of no-clean flux is that it saves the time and cost of cleaning, reduces environmental pollution and improves productivity.

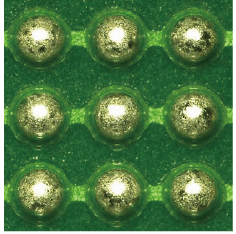

So, is it necessary to clean no-clean flux? The answer is: it depends. Although the residue of no-clean flux has a low impact on the performance of the board, it does not mean that it is completely harmless. Residues of no-clean flux still contain a certain amount of active substances, such as acids, halogens, metal ions, etc., which may cause corrosion, leakage, short-circuiting and other problems on the circuit board under certain conditions.

Figure 2. Flux Residue

1. The environment in which the circuit board is used: If the circuit board needs to be used in high temperature, high humidity, high salt and other harsh environments, then it is recommended to clean the residues of the no-clean flux to prevent the residues from reacting with the environmental factors, resulting in damage to the circuit board.

2. The use of circuit board requirements: in high-voltage, high-frequency, high-speed and other high-performance occasions, no-clean flux residues may affect the signal transmission and stability of the circuit board, reducing the performance and reliability of the circuit board. In order to ensure that the circuit board works, it is recommended to clean the circuit board.

3. The service life of the circuit board: If the circuit board needs to be used or stored for a long time, then it is recommended that it be cleaned in order to extend the service life and reliability of the circuit board.

If you need to clean the no-clean flux, then you should choose the appropriate cleaning method and cleaner. Generally speaking, there are the following common cleaning methods:

1. Water cleaning method: use deionized or purified water as a cleaning agent, through spraying, soaking, brushing and other ways to flush out the residue. This method is simple, cheap, environmentally friendly, but the effect is not thorough enough, may leave water stains or scale.

2. Solvent cleaning method: use a special solvent as a cleaning agent, through spraying, soaking, brushing and other ways to dissolve the residue off. This method is more effective and can remove most of the residue, but the cost is higher and may cause damage to the circuit board or human body.

3. Ultrasonic cleaning method: the use of water or solvent as a cleaning agent, through the mechanical vibration of ultrasound and chemical action to break down the residue. This method is the most effective and can remove almost all the residues, but the equipment is more expensive and the operation is more complicated.

Shenzhen Fitech flux products cover no-wash and water-wash type, rosin and epoxy resin type, which can meet different soldering needs and standards. If you want to know more about our flux or solder paste products and services, please feel free to call us.

Back to list

Back to list