Improvement of Sn-Bi Low-Temperature Solder Paste by Adding Ag and In_Shenzhen Fitech

Improvement of Sn-Bi Low-Temperature Solder Paste by Adding Ag and In_Shenzhen Fitech

Sn-Bi eutectic solder paste has low soldering temperature requirements and can be soldered at low temperatures. This solder paste is important in the solder market due to its advantages, such as low-temperature soldering and high tensile strength. However, Bi is a brittle metal and prone to segregation in the solder during the heating process. The localized Bi phase segregation and coarsening causing solder joint brittleness affect the application of Sn-Bi eutectic solder paste. Fortunately, adding some particles to Sn-Bi eutectic solder can enhance the solder strength.

Experimental Design

The most widely used low-temperature solder paste is made based on SnBiAg and SnBiAgIn alloys. This solder paste is added with a small amount of Ag and In on the basis of Sn42Bi58 eutectic solder paste to improve the physical properties. Hu et al. prepared a series of low-temperature solder alloys and verified their mechanical strength.

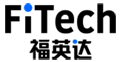

Table 1. Experimental solder alloys.

Results

Microstructure

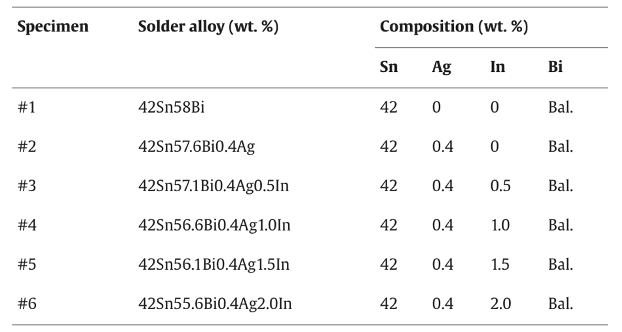

The main microstructure of Sn-Bi solder alloy is Bi-rich and Sn-rich phases, with a layered arrangement structure. After heating and soldering with ordinary Sn42Bi58 solder, coarse Bi-rich phases can be clearly observed in the solder joint matrix. After adding a small amount of Ag, the coarse Bi phase is significantly reduced, which means that the coarsening of the rich Bi phase is effectively suppressed.

Figure 2. Microstructure of different solders. (a)42Sn58Bi; (b)42Sn57.6Bi0.4Ag; (c)42Sn57.1Bi0.4Ag0.5In; (d)42Sn56.6Bi0.4Ag1.0In; (e)42Sn56.1Bi0.4Ag1.5In; (f)42Sn55.6Bi0.4Ag2.0In.

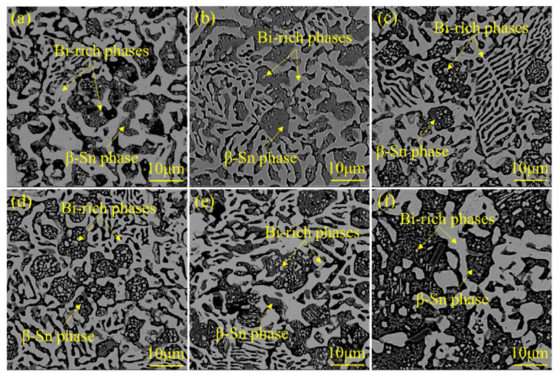

After conducting a tensile test, the fracture morphology of the solder joint can be observed through SEM. From Figure 3a, it can be seen that the cleavage surface of the solder joint (where the crystal ruptures along a certain crystal direction under external force and can crack into smooth planes) is mainly caused by the hard and brittle fracture of the Bi-rich phase. Meanwhile, in some sections β-ductile fracture morphology was observed on the Sn phase. With the addition of Ag, the cleavage surface generated by the coarse Bi-rich phase slightly decreases (Figure 3b), as shown in Figure 3(c-f). After the addition of In, there was no significant change in the fracture of Sn Bi solder alloy, and few pits were observed. Due to the similarity in atomic number between In and Sn, it is easy to dissolve in the Sn matrix during solidification. Therefore, In can soften the Sn matrix to improve ductility and reduce the influence of Bi.

Figure 3. Different solder fracture surfaces. (a)42Sn58Bi; (b)42Sn57.6Bi0.4Ag; (c)42Sn57.1Bi0.4Ag0.5In; (d)42Sn56.6Bi0.4Ag1.0In; (e)42Sn56.1Bi0.4Ag1.5In; (f)42Sn55.6Bi0.4Ag2.0In.

Mechanical properties

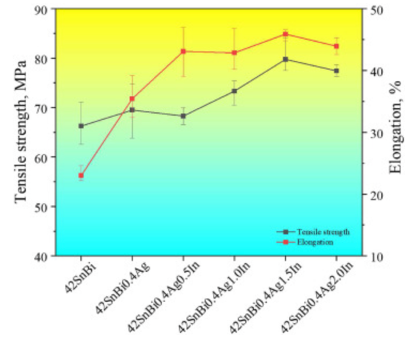

The tensile strength and elongation of ordinary SnBi eutectic solder alloys are approximately 66.2MPa and 23.0%. After adding 0.4 wt.% Ag, the tensile strength and elongation of the solder alloy can be improved, indicating that Ag is beneficial for improving the mechanical properties of the solder alloys. Since Ag and Sn form Ag3Sn IMC in the solder matrix, the microstructure of the solder alloy is refined, and the strength of the solder joint. In addition, adding In on top of SnBiAg0.4 also increases the tensile strength and elongation of the solder alloys. With the addition of In increasing to 1.5%, the properties of the solder alloy are further improved. However, it should be noted that In is relatively soft, and excessive addition can easily have a negative impact on the strength of the solder joint.

Figure 4. Mechanical properties of different solders. (a)42Sn58Bi; (b)42Sn57.6Bi0.4Ag; (c)42Sn57.1Bi0.4Ag0.5In; (d)42Sn56.6Bi0.4Ag1.0In; (e)42Sn56.1Bi0.4Ag1.5In; (f)42Sn55.6Bi0.4Ag2.0In.

Low-temperature solder paste

Shenzhen Fitech can provide customers with SnBi57.6Ag0.4 low-temperature solder alloy and solder paste products. Fitech’s low-temperature solder alloy has high sphericity, smooth surface, and low oxygen content, and can be made into ultrafine solder paste (T6 and above) for printing and dispensing processes. Fitech’s low-temperature solder paste has stable viscosity and thixotropy properties, which can meet customers' requirements for fine-pitch soldering.

Reference

Hu, T.H., Li,S., Li, Z., Wu, G.Z., Zhu, P., Dong, W.F, Sun, Y., Zhou, J.Y., Wu, B.J., Zhao, B.G., Ding, K. & Gao, Y.L. Coupled effect of Ag and In addition on the microstructure and mechanical properties of Sn–Bi lead-free solder alloy. Journal of Materials Research and Technology, vol. 26.

Back to list

Back to list