Solder Paste for MEMS Package: Atomic Layer Deposition Process Assists PowderMEMS

Solder Paste for MEMS Package: Atomic Layer Deposition Process Assists PowderMEMS

Solder Paste and Ultra-Fine Solder Manufacturer-Shenzhen Fitech is a comprehensive solder paste supplier integrating production, sales, research, and service of solder paste, epoxy solder paste, and solder powder. Fitech is the leading unit for the formulation of solder powder standards of the Ministry of Industry and Information Technology. Fitech's products include ultra-fine lead-free printing solder paste, ultra-fine lead-free dispensing solder paste, ultra-fine lead-free jetting solder paste, ultra-fine lead-free pin transfer solder paste, no-clean solder paste, water-soluble solder paste, high-temperature solder paste, medium-temperature solder paste, low-temperature solder paste, etc. Fitech can manufacture electronic-grade packaging solder powders with particle sizes from T2-T10.

According to Memes Consulting, the Fraunhofer Institute for Silicon Technology (ISIT) in Germany announced the use of the PICOSUN P-300B ALD system for its PowderMEMS technology platform.

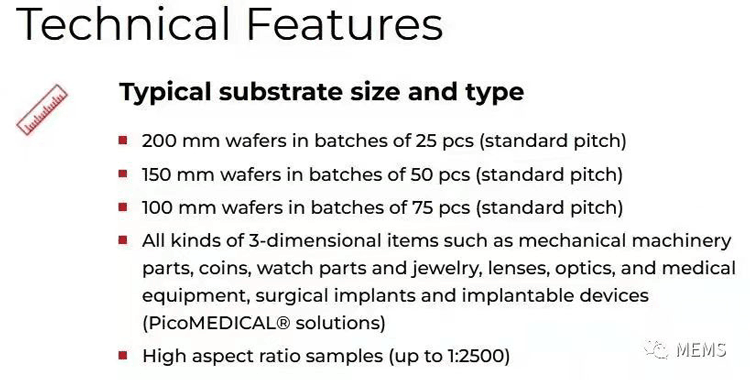

PICOSUN P-300B ALD and its features

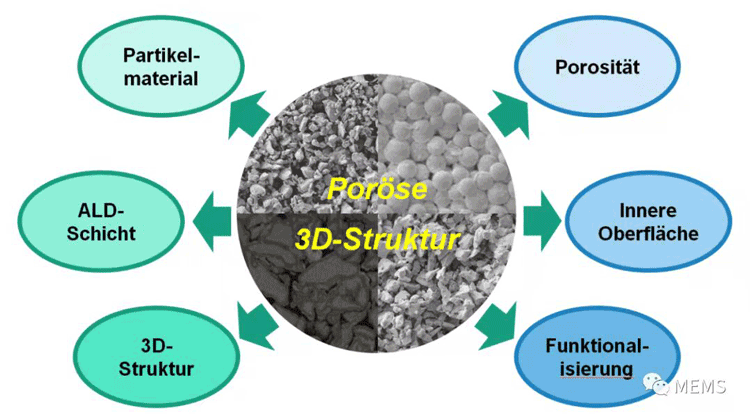

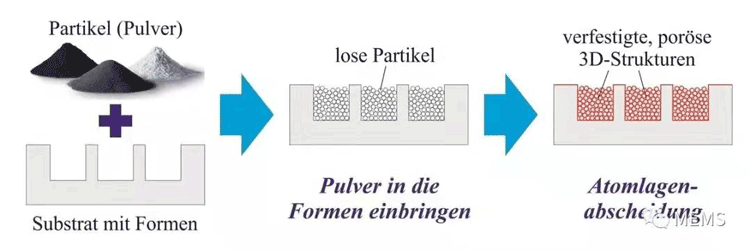

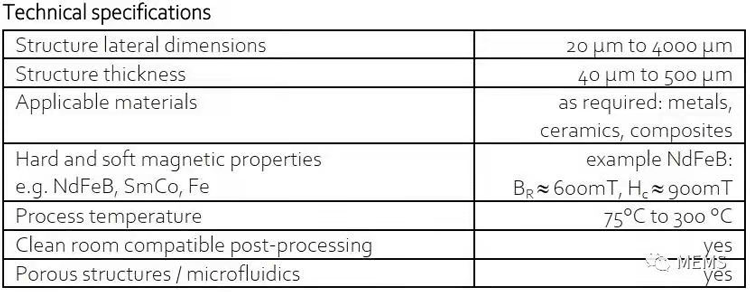

PowderMEMS from Fraunhofer ISIT is a new innovative technology for creating three-dimensional microstructures from a variety of materials at the wafer level. The technology is based on bonding micron-sized powder particles together in cavities through an atomic layer deposition (ALD) process. PowderMEMS has many advantages over other fabrication techniques because it allows the use of much lower process temperatures than traditional sintering processes. The bonded porous structure is thermally and chemically resistant, allowing extensive post-processing in cleanrooms.

PowderMEMS technical specifications

"PowderMEMS can be used in a variety of MEMS applications, including sensors, actuators, energy harvesters, microfluidics, microelectronics, etc. For example, it enables the integration of porous and magnetic 3D microstructures at the wafer level," said Dr. Björn Gojdka, Fraunhofer ISIT group lead.

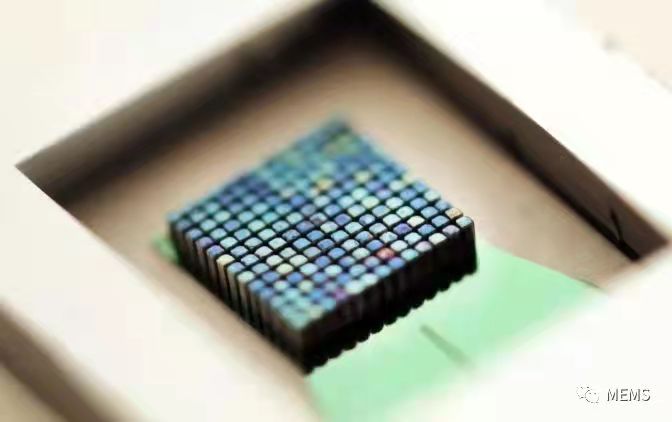

MEMS energy collector with integrated micromagnet

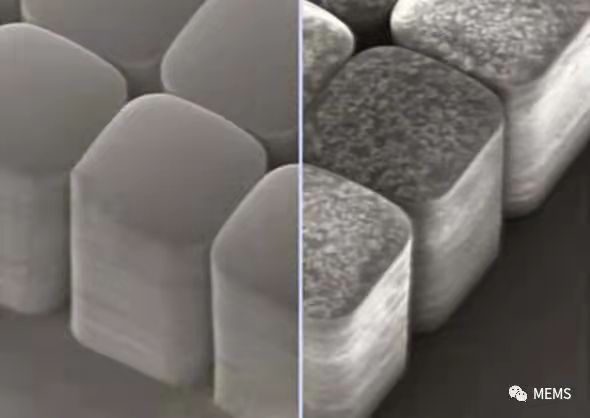

Microstructure of magnetic PowderMEMS

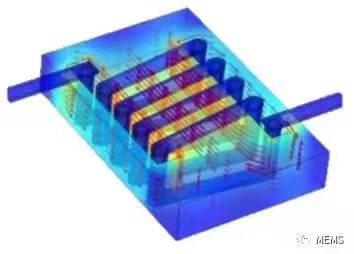

Microcoil with integrated soft core

“We were looking for a solution for conformal high surface area coating of powders in trenches. Picosun’s ALD solution was a perfect fit for our needs, and we were also looking into scaling up the technology. I am particularly satisfied with the ALD system's hot wall reactor, versatile precursor source, ease of maintenance, etc." said Dr. Thomas Lisec, Chief Scientist at Fraunhofer ISIT.

Dr. Christoph Hossbach, Managing Director of Picosun Europe, said: "We are excited about the birth of this new technology and all the opportunities it brings. I am particularly impressed with the potential applications of Fraunhofer ISIT's PowderMEMS technology because it is so diverse. I am looking forward to continuing to work closely with Fraunhofer ISIT."

Source:MEMS

Back to list

Back to list