Solder Paste for Mini-LEDs: Vehicle Display Screens Prefer to Mini/Micro LED

Solder Paste for Mini-LEDs: Vehicle Display Screens Prefer to Mini/Micro LED

Solder Paste and Ultra-Fine Solder Manufacturer-Shenzhen Fitech is a comprehensive solder paste supplier integrating production, sales, research, and service of solder paste, epoxy solder paste, and solder powder. Fitech is the leading unit for the formulation of solder powder standards of the Ministry of Industry and Information Technology. Fitech's products include ultra-fine lead-free printing solder paste, ultra-fine lead-free dispensing solder paste, ultra-fine lead-free jetting solder paste, ultra-fine lead-free pin transfer solder paste, no-clean solder paste, water-soluble solder paste, high-temperature solder paste, medium-temperature solder paste, low-temperature solder paste, etc. Fitech can manufacture electronic-grade packaging solder powders with particle sizes from T2-T10.

Cars are less like cars.

Nowadays, the automobile industry is developing in the direction of the new four modernizations. The so-called new four modernizations can be described as electrification, networking, intelligence, and sharing, which are based on electrification, taking networking as a link to collect big data to ultimately realize an intelligent and shared travel mode. Under this trend, people are surprised to find that cars are no longer just a means of travel but have the attributes of digital products.

On the other hand, as an important medium for human-vehicle interaction, the manifestation of automobile futuristic and technological sense presents the development trend of the large screen, multi-screen, high-definition, interaction, low energy consumption, and multi-form. The automotive screen has become the fifth largest small and medium panel market after the mobile phone and tablet itor.

However, the final technical solution adopted for the automotive screen has not yet been determined.

Which Scree Technology Represents the Future?

As a mature display technology, LCD is currently the mainstream technology for car screens. It has established a relatively complete standard system with stable quality, guaranteed production capacity, and obvious cost advantages.

However, with the advent of the new four modernizations of automobiles, LCD technology cannot meet the needs of high-end automobiles for display systems because of insufficient brightness output, rapid temperature rise, and limited visual effects. In this case, the advantages of OLED, mini-LED, and micro-LED are attracting people's attention to the car screen application.

Each of these three techniques has advantages and disadvantages. OLED is an organic self-luminous display technology, which has the advantages of good display effect, low power consumption, high flexibility, and ultra-lightweight. It can be used for the large waterfall screen in Mercedes-Benz, such as a 12.8-inch waterfall OLED screen. The Mercedes-Benz EQS adopts an integrated screen from the A-pillar to the A-pillar, and the touch screen is a flexible OLED.

The main suppliers of OLED automotive screens are Samsung, LGDisplay, JD.COM, etc. However, after years of development, OLED has failed to solve the problem of screen burn-in. Besides, the blue light life of OLED is low, which hinders the further development of OLED screens in the automotive field.

Mini-LED can be matched with flexible substrates to realize curved display design, improving screen brightness, contrast ratio, and screen design flexibility. However, mini-LED screens are thick and cannot be greatly bent compared with OLEDs.

It should be noted that the technology suitable for car screens is mini-LED backlight technology instead of mini-LED direct display technology because the viewing distance of the mini-LED backlight screen is relatively short. However, the pitches of the mini-LED direct display technology are large. Moreover, the pixel points of direct display screens are obvious when viewed at a close distance. The LED direct display solution of the car screen needs to reach the micro level.

Micro-LED is a miniature and matrix LED technology with greater advantages in brightness, resolution, contrast ratio, energy consumption, lifetime, response speed, and thermal stability. However, micro-LED technology is difficult with low output and high price. Hence, it has not yet reached the mass production standard.

Vehicle-mounted displays require high brightness, long service life, fast response time, and a wide range of high and low temperatures. It has high requirements for display technology. As far as the current level of development is concerned, OLED, mini-LED backlight, and micro-LED have limitations. In contrast, OLED technology has been popularized and is a relatively mature technology. Mini-LED backlights and micro-LED are still in the early stage of the industry, and there is great potential for product performance improvement.

SAC Solder Paste SnBiAg Solder Paste SnBiAgSb Solder Paste SnBiAgX Solder Paste SnBi Solder Paste BiX Solder Paste AuSn Solder Paste SnSb Solder Paste SnPb Solder Paste Anisotropic Conductive Paste Ultra-Fine-Pitch Flux

Mini-LED Backlight and Micro-LED Develop Quickly.

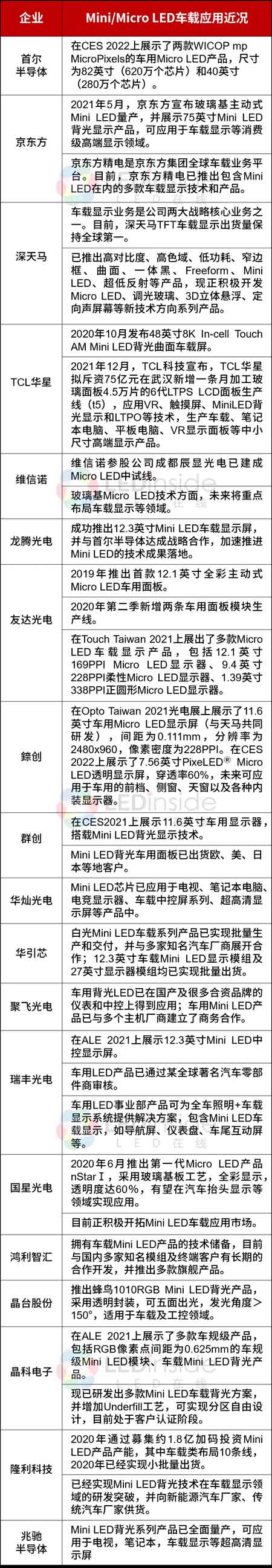

Related companies are accelerating the deployment of automotive mini-LED backlights and micro-LED technology. According to incomplete statistics from LEDinside, the mainstream suppliers of mini-LED backlights and micro-LED for vehicles and their current status are as follows.

It can be seen that whether it is an international company or a Chinese company, whether it is a panel manufacturer or a traditional LED manufacturer, they are actively deploying automotive mini-LED backlights, micro-LED technology, and products.

On the other hand, due to the technical difficulty, industrial chain companies are overcoming industrial problems through win-win cooperation.

Tianma held the 2021 MicroLED Ecological Alliance Conference in December 2021. At the meeting, Tianma cooperated with upstream suppliers, downstream automobile companies, and university research institutions to establish a micro-LED ecological alliance to accelerate the application of micro-LEDs in-vehicle displays. At the event site, Tianma released many new products, such as micro-LED screens with more than 70% transparency, micro-LED splicing unit screens, high-resolution micro-LED screens, etc.

In 2019, Tianma exhibited a 7.56-inch micro-LED screen at SIDisplayWek 2019 with a transmittance of over 60%. Besides, Tianma launched an 11.6-inch micro-LED screen at Opttaiwan in 2021.

It can be seen that whether it is an international company or a Chinese company, whether it is a panel manufacturer or a traditional LED manufacturer, they are actively deploying automotive mini-LED backlights, micro-LED technology, and products.

In addition, MicroLOD display technology research and development reached cooperation with friends in April 2020. In December 2020, a four-year long-term cooperation plan was signed with the Taiwan Industrial Research Institute, focusing on the application of AR, MR equipment, and vehicle panels.

Longli Technology has also welcomed allies in the panel field. In April 2021, the innovation laboratory for small and medium display technology development jointly built by CSOT and Longli Technology was officially opened. The joint innovation laboratory is committed to the research and development of cutting-edge technologies in the backlight display industry, focusing on the development of mini-LED technology, including mobile phones, tablet computers, notebook computers, automotive displays, VR displays, and AR wearable displays.

As a panel company, JD.COM formed a joint venture BOEPixey with Rohini in 2019 to develop micro-LED solutions for backlight displays, which are initially designed for large-scale consumer electronics (above 32 inches), industrial, and automotive markets.

Conclusion

For mini/micro-LED supply chain companies, although the certification time is long, the product life cycle is long, and the technical content and the profit margin are high. Thus, mini/micro-LED is a battleground for companies.

However, micro-LED technology is too difficult. There is no mass-produced car equipped with micro-LED technology yet, while mini-LED is already on the eve of its application. For example, the Weilai ET7, which will be officially released in January 2021, adopts BOE (JD.COM) 10.2-inch HDR mini-LED backlight digital meter.

In addition, mini-LED screens can also be applied to the exterior of the vehicle, adding fun to the car design. In November 2021, the first mecha dragon of Great Wall's high-end brand salon was officially unveiled. The rear of the model adopts mini-LED external display technology, and the intelligent taillights can freely define the display content.

In-vehicle screens have become the key for mini/micro-LED to grow in the market. It is conceivable that when mini/micro-LED further develops, especially when microLED breaks through the technological bottleneck, it will become a strong competitor in the OLED vehicle display market.

Source: LEDinside, retrieved by Fitech

Back to list

Back to list