Why Should We Care about Solder Paste Thixotropy?

Why Should We Care about Solder Paste Thixotropy?

Thixotropy is a property present in fluids. When subjected to shear, fluids undergo viscosity changes. The viscosity recovers after the shear forces are removed. The common shear impacts are shear thinning and shear thickening, corresponding to the viscosity decreases or increases, respectively. The thixotropy property is caused by the accumulation of suspended particles, which structure is affected by the attractive and repulsive forces between the particles. Suspended particles maintain a grid structure without external force, but the structure deforms when shearing.

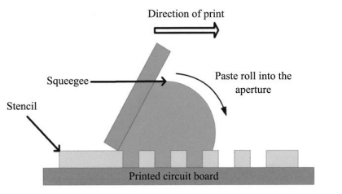

Solder paste is a material widely used in semiconductor packaging to connect the components and substrates. Through the printing process, the solder paste can uniformly fill the pads. Thixotropy plays an important role in solder paste printing. Since solder paste is usually shear thinning, when a squeegee is used to fill the solder paste into the stencil apertures, the shear force exerted by the squeegee significantly reduces the viscosity of the solder paste so that the solder paste can smoothly enter the apertures. Therefore, the pros and cons of thixotropy largely determine the printing quality. In order to produce solder paste with proper thixotropy, a thixotropic agent needs to be added to emulsify the flux. Therefore, the solder paste can have long-term stable thixotropic properties during printing. If the effectiveness of the thixotropic agent is weakened, the viscosity will degrade. The identified method of the viscosity increases is that the solder paste becomes dry.

Figure 1. Schematic diagram of solder paste printing.

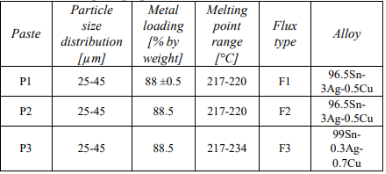

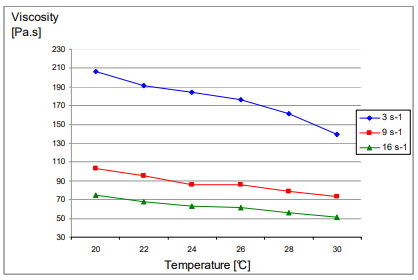

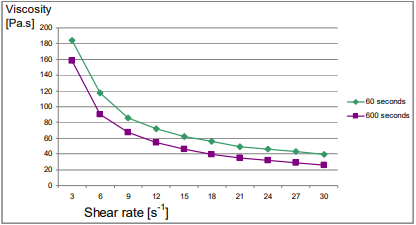

Temperature and shear forces are the core external factors to influence thixotropy. KRAVCIK and VEHEC (2010) conducted viscosity tests on solder pastes (the solder paste properties are shown in Table 1). It was found that the viscosity gradually decreased as the temperature or shear force increased. When both temperature and shear force increased, the viscosity values became smaller (Figure 2). KRAVCIK and VEHEC (2010) also found that viscosity is related to shear time. As the shear time increases, the viscosity will be lower.

Table 1. Experimental Solder Paste Properties.

Figure 2: Viscosity changes of P1 solder paste with different shear force. Shear rate: 3s-1, 9s-1, 16s-1.

Figure 3: The relationship between P1 solder paste viscosities and shear time at 24℃.

In addition, some researchers believe that particle size also affects viscosity. Krammer et al. (2018) highlighted that the viscosity differences between solder pastes with different particle sizes can reach 20-30% (T3, T4, and T5 powders) under stable conditions (after 4-5 test cycles). As research progresses, more data may be available to verify the effect of particle size on viscosity.

Fitech provides high-quality ultra-fine solder paste for semiconductor packaging with superior printing effect and high solder joint reliability. Welcome to consult relevant information.

Reference

Krammer, O., Gyarmati, B., Szilagyi, A., Illes, B., Busek, D., & Dusek, K. (2018), “The effect of solder paste particle size on the thixotropic behaviour during stencil printing”, Journal of Materials Processing Technology, vol. 262, pp.571-576.

KRAVCIK, M., & VEHEC, I. (2010), “Study of the Rheological Behaviors of Solder Pastes ”

Back to list

Back to list