Effects of Sn Nano-Particle on Lead-Free Solder Paste

Effects of Sn Nano-Particle on Lead-Free Solder Paste

Tin-silver-copper solder paste (SAC) is one of the most commonly-used lead-free solders pastes in semiconductor packaging. SAC solder paste has a medium soldering temperature and is suitable for components operating under various medium temperature conditions. The reliability of solder joints after soldering has always been a hot topic in the industry. There is a common consequence that conventional SAC solder pastes rapidly degrade in strength after thermal aging. The reason is a large amount of brittle IMC Cu3Sn growth at the solder joints and PCB interfaces. IMC is an important factor affecting the reliability of solder joints. As the aging time increases, the IMC gradually gets thicker, resulting in brittle fracture of the solder joints.

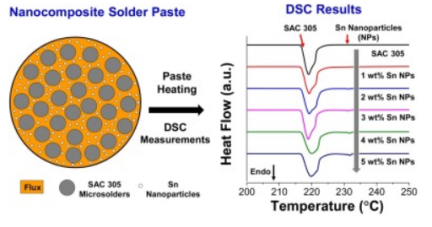

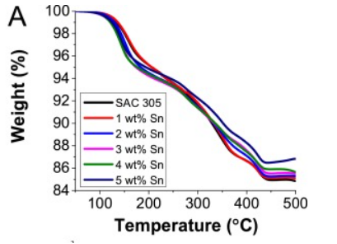

There were so many discussions about nanoparticles in recent years. The researchers sought to understand the effects of nanoparticles addictive on the solder paste properties. It was found that the addition of Sn nanoparticles caused a second endothermic peak because of the melting of nanoparticles, and the peak value grew with the increase of particle addition (Wernicki & Gu, 2020). In addition, the melting range expanded with the increase of the additive amounts. Wernicki and Gu's follow-up experiments show that the melting of the nanocomposite solder generated a new endothermic peak different from that of SAC solder paste and Sn nanoparticles, indicating that the SAC alloy and Sn nanoparticles interacted and formed a new alloy. As the heating progressed, the nanocomposite solder paste had better weight retention (Figure 2).

Figure 1: Solder paste with nanoparticles and its DSC results. The second endothermic peak was caused by the melting of nanoparticles (Wernicki & Gu, 2020).

Figure 2: TGA analysis of SAC305 solder paste with different nanoparticle additive amounts (Wernicki & Gu, 2020).

Nano-additives can improve the reliability of solder joints. Atieh et al. (2019) added 10wt% Sn nanoparticles (particle size <150nm) to SCAN-Ge071-XF3+ solder paste. The experimental results show that Sn nanoparticles improve the highest strength of the solder paste, and the surface successfully passed the mechanical impact test. Instead of Sn nanoparticles, there are many other types of nanoparticles that can be used to optimize solder paste performance and improve solder joint reliability. For example, Chellvarajoo et al. (2015) investigated the effect of Fe2NiO4 nanoparticles on SAC305 solder paste. The result shows that the IMC thickness was reduced by 59% after adding 2.5wt% Fe2NiO4 nanoparticles to the SAC305 solder.

Fitech adopts a new composite solder method by adding several nanoparticle elements to the tin-bismuth alloy (Sn42Bi28), which effectively inhibits Bi segregation, thereby slowing down the growth rate of IMC and avoiding the formation of brittle solder joints. Welcome to consult and understand related solder paste products.

Reference

Atieh, A.M., Abedalaziz, T.J., AIHazaa, A., Weser, M., Al-Kouz, W.G., Sari, M.S., & Alhowemi, I. (2019), “Soldering of Passive Components Using Sn Nanoparticle Reinforced Solder Paste: Influence on Microstructure and Joint Strength”, Nanomaterials, 9(10),1478.

Chellvarajoo, S., Abdullah, M.Z., & Samsudin, Z. (2015), “Effects of Fe2NiO4 nanoparticles addition into lead free Sn–3.0Ag–0.5Cu solder pastes on microstructure and mechanical properties after reflow soldering process”, Maters & Design, vol.67, pp. 197–208.

Wernicki, E., & Gu, Z.Y. (2020), “Effect of Sn nanoparticle additions on thermal properties of Sn-Ag-Cu lead-free solder paste”, Thermochimica Acta, vol. 690.

Back to list

Back to list