Solder Paste Creep and Nano-Enhanced Method

Solder Paste Creep and Nano-Enhanced Method

With the development of semiconductor technology, the scenarios using electronic devices are becoming more extensive. It leads to the increased exposure of electronic components to high-temperature conditions. Continuous thermal cycling can cause thermal contraction and expansion of electronic components (PCB substrates and solder joints). Therefore, it is necessary to test the reliability of the solder joints after the soldering to ensure that the solder joints can withstand a certain number of thermal cycles. Thermal creep is a negative effect that can lead to solder joint failure and therefore requires special attention. This article will briefly discuss the thermal creep phenomenon of solder paste alloys and the methods to improve the creep performance of solder paste alloys.

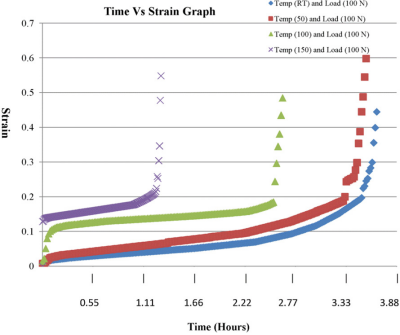

Temperature changes create thermal stress at the solder joints due to mismatches in the thermal expansion coefficients of the solder paste alloys and the substrates. These stresses can cause grain boundary sliding in the solder paste alloys to form dislocations and creep, leading to cracks. Mazulah et al. (2021) fabricated solder joints using Sn95.5Ag3.8Cu0.7 solder paste and performed thermal aging tests. They found that the strain stress of the solder joints increased with aging time, and the strain rises faster at high temperatures. Eventually, solder joint fracture occurs. From Figure 1, it can be judged that the creep of solder paste alloys is tightly related to temperature, load, and time.

Figure 1: The relationship between strain and tim at different temperatures.

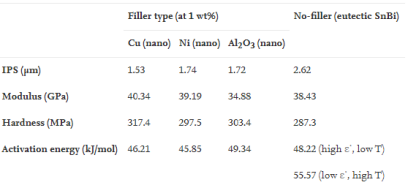

Low-temperature solder paste is a promising type of solder, but it is susceptible to creep. Therefore, some scholars try to improve the creep resistance of solder paste alloys by means of additives. Shen et al. (2017) used non-reactive Al2O3 nanoparticles as a filler to improve the creep resistance of eutectic SnBi solder paste alloys. They mixed SnBi alloys with Al2O3 nanoparticles. Non-reactive fillers do not form new compounds with the alloy but can still improve mechanical properties. Shen et al. highlight that Al2O3 nanoparticles can effectively refine the alloy microstructure to reduce the alloy interphase spacing (IPS) and increase the hardness (Table 1).

Table 1. The effects of various fillers on eutectic SnBi solder paste properties.

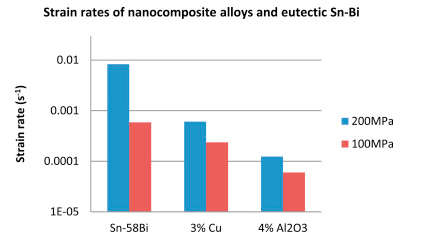

Shen et al. found that the strain rate of solder joints decreased significantly at room temperature after adding 4wt% Al2O3 nano-particles to the solder paste (Figure 2). Al2O3 nanoparticles can accelerate the alloy to form a discontinuous layered structure, which can inhibit creep. Al2O3 nanoparticles can limit diffusion creep through the pinning effect and inhibit recrystallization at grain boundaries, thereby enhancing the strength of solder joints.

Figure 2. Strain rate comparisons between SnBi eutectic solder paste and nano composite solder.

Fitech can provide Nano-enhanced solder paste. The resulting solder joints have high reliability and can meet different packaging requirements.

Mazullah, Sadiq, M., Khan, M., Mateen, A., Shahzad, M., Akhter, K., & Khan, J. (2021), “Thermal aging impact on microstructure, creep and corrosion behavior of lead-free solder alloy (SAC387) use in electronics”, Microelectronics Reliability, vol.122.

Shen, L., Foo, A.Q., Wang, S.J., & Chen, Z. (2017), “Enhancing creep resistance of SnBi solder alloy with non-reactive nano fillers: A study using nanoindentation”, Journal of Alloys and Compounds, vol.729, pp.498-506.

Back to list

Back to list