Wall-Slip Effect of Lead-Free Solder Paste

Wall-Slip Effect of Lead-Free Solder Paste

Due to the great demand for solder paste in electronic packaging, it is necessary to have a good check on the properties of solder paste, thereby reducing the defect rate after soldering. During the printing process, the rheological properties of the solder paste require special attention. Rheology largely determines the print quality and solder joint reliability after soldering. Wall slip has an influence on the accuracy of the instrument to measure the rheological properties of solder paste materials and the printing quality. The wall-slip issue arises because of the complex interaction of attractive and repulsive forces between solder paste particles and geometries. Barnes (1995) believed that the geometrical structure causes a low-viscosity depletion layer between the wall and the bulk fluid as a result of space, hydrodynamics, gravity, and other reasons and creates a sliding effect. Wall slip usually occurs at the interface between the solder paste sample and the measurement part.

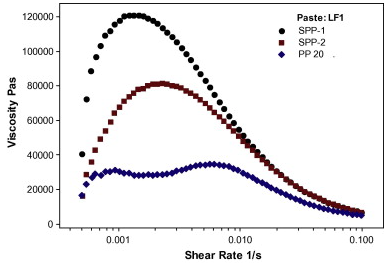

Factors affecting the sliding effect of solder paste mainly include large particles acting as the dispersed phase, low flow rates, and electrostatically-charged particles and walls (Barnes, 1995). Barnes believes that smooth geometries are more susceptible to sliding effects. Therefore, some researchers consider that the roughening of the solder paste geometry can effectively reduce the slip effect. Mallik et al. (2009) used three different geometries to conduct rheological tests on Sn96.5Ag3Cu0.5 solder paste, including smooth parallel plate (PP20), serrated parallel plate No. 1 (Serrated parallel plate) -1, SPP-1), and serrated parallel plate-2 (SPP-2). It can be found from Figure 1 that the viscosity of the solder paste increases and then decreases with the change of the shear rate by using a serrated-structure measurement part and then shear thinning occurs when it reaches the critical value. However, the smooth structure exhibits viscosity discontinuities. Mallik et al. believe that the phenomenon is caused by the wall-slip effect, and the roughened structure is able to maintain a sufficient grip on the solder paste when shearing forces are applied.

Figure 1. Shear Rate vs. viscosity for different geometry.

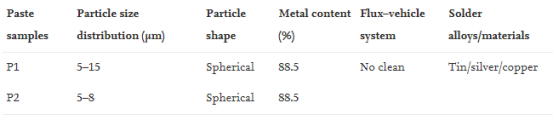

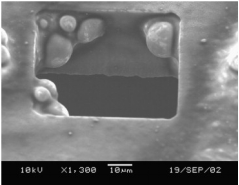

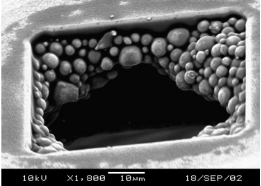

Durairaj et al. (2010) used a stress rheometer with a 40mm in diameter parallel plate and a printer to perform rheological and printing tests on the two solder pastes (the solder paste parameters are shown in Figure 2). It was calculated that the real viscosity of the two solder pastes was much larger than that of the simulated results, which was likely to be caused by the wall-slip effect. Meanwhile, slippage has a significant impact on the solder paste volume printed on the pads. Durairaj et al. conducted printing tests and found that P1 slipped faster than P2 and formed better-printed dots because P1 had less solder paste attached to the aperture wall. Therefore, appropriate slippage has a positive effect on printing performance.

Figure 2. P1 and P2 solder paste features.

Figure 3. Aperture residue after printing, P1(left), P2(right).

Fitech is committed to producing ultra-fine solder paste with high reliability and excellent rheology. Fitech’s specialists can adjust the solder paste parameters to satisfy customer requirements. Welcome to consult and learn more information.

Reference

Barnes, H.A. (1995), “A review of the slip (wall depletion) of polymer solutions, emulsions and particle suspensions in viscometers: its cause, character, and cure”, Journal of Non-Newtonian Fluid Mechanics, vol.56(3), pp.221-251.

Durairaj, R., Man, L.W., Ekere, N.N., & Mallik, S. (2010), “The effect of wall-slip formation on the rheological behaviour of lead-free solder pastes”, Materials & Design, vol.31(3), pp.1056-1062

Mallik, S., Ekere, N.N., Durairaj, R., Marks, A.E., & Seman, A. (2009), “Wall-slip effects in SnAgCu solder pastes used in electronics assembly applications”, Materials & Design, vol.30(10), pp.4502-4506.

Back to list

Back to list