Features and Advantages of Halogen-Free Lead-Free Solder Paste

Features and Advantages of Halogen-Free Lead-Free Solder Paste

The packaging of components requires a large amount of solder paste. As we all know, solder paste is produced by mixing alloy powder and flux in specific proportions. The choice of flux influences the soldering performance. Solder paste forms metallurgical solder joints after soldering, but the non-volatile components of the flux become residues. Many packaging manufacturers have high restrictions on residues after soldering, especially halogen components. Halogen residues will continuously corrode the solder joints, thereby reducing the reliability. Therefore, the flux composition of the solder paste needs to follow the halogen-free formula. The chlorine and the bromine contents must be less than 900ppm, and the total should not exceed 1500ppm. Additionally, with the popularity of lead-free, lead-free solder paste has become the mainstream packaging material, and the combination of lead-free and halogen-free is very popular.

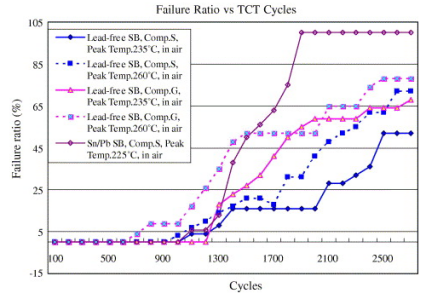

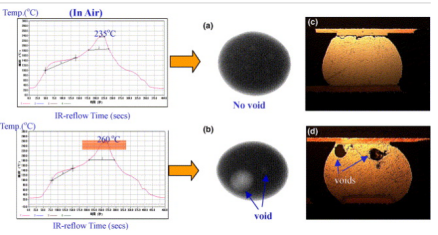

Reflow temperatures have potential impacts on the solder joint reliability. In the case of different reflow peak temperatures, it can be seen from Figure 1 that the lead-free halogen-free solder joints formed at lower temperatures have lower failure rates. Compared with leaded solder paste, lead-free solder paste is more reliable after soldering. Hence, it can withstand more thermal cycles and has a lower failure rate than leaded solder paste (Chung et al., 2005). High temperatures accelerate the growth of intermetallic compounds and the formation of voids. Large-area cracks appear in the solder joints after thermal cycling aging.

Figure 1. Solder paste reliability test at different peak reflow temperatures (Chung et al., 2005).

Figure 2. X-ray scanning images of solder joints after thermal-cycling, 235℃ (a), (c); 260℃ (b), (d) (Chung et al., 2005).

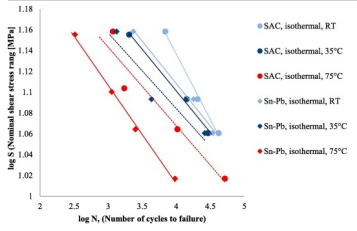

Ghaleeh et al. (2020) also conducted experiments and found that the fatigue resistance of lead-free solder paste was better than that of leaded solder paste. After taking the logarithm of stress and cycles to failure, the relationship was obtained. The reliability of both leaded and leaded solder pastes decreased with increasing stress. However, lead-free solder pastes performed better than leaded solder pastes at the same temperature.

Figure 3. Stressing performance of SnAg3.8Cu0.7 and SnPb37 Solder Pastes (Ghaleeh et al., 2020).

Although leaded solder paste still has some unique advantages, lead-free solder has been able to gradually replace leaded solder with long-term development. Fitech provides high-quality lead-free ultra-fine solder pastes made of halogen-free or zero-halogen formula. After soldering, the solder joints are highly reliable, and the residues are easy to clean. Welcome to acquire more information.

Reference

Chung, C.L., Lu, L.T., & Lee, Y.J. (2005), “Influence of halogen-free compound and lead-free solder paste on on-board reliability of green CSP (chip scale package)”, Microelectronics Reliability, vol.45 (12), pp.1916-1923.

Ghaleeh, M., Baroutaji, A., & Qubeissi, M.A. (2020), “ Microstructure, isothermal and thermomechanical fatigue behaviour of leaded and lead-free solder joints”, Engineering Failure Analysis, vol.117.

Back to list

Back to list