BGA Solder Paste_The Effect of Solder Joint Height on Solid-Liquid Diffusion

BGA Solder Paste_The Effect of Solder Joint Height on Solid-Liquid Diffusion

Solder paste is used in most cases in SMT and BGA operations to connect chips and substrates. After reflow soldering is completed, the solder pastes solidify into solid solder joints with excellent electrical conductivity. The properties of solder joints determine whether the properties, such as mechanical strength, can meet the requirements. Diffusion at the solid-liquid interface is one mechanism that occurs during reflow. Copper pad atoms dissolve into the solder and form specific intermetallic compounds (IMCs). The evolution of IMCs at the solder joint interface has a geometric size effect during aging. The size effect of interfacial diffusion mainly focuses on the influence of solder joint volume and pad metallization layer thickness on interfacial diffusion. To gain insight into the effect of solder joint height on solid-liquid diffusion. Li et al. tested the influence of different heights of SAC305 solder joints on the solid-liquid interface diffusion.

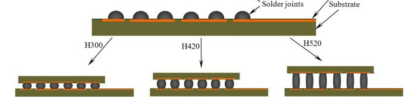

Figure 1. Solder joints for testing. H300: Height = 300μm; H420: Height = 420μm; H520: Height = 520μm

Experimental Results

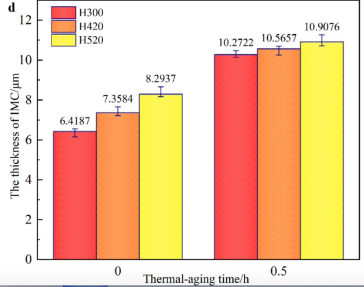

After aging at 230°C for 0.5 h, the IMC thicknesses of H300, H400, and H520 solder joints were 6.419μm, 7.358μm and 8.294μm, respectively, and the corresponding copper pad consumptions were 3.691μm, 4.069μm and 4.553μm, respectively. It can be seen that the higher the solder joint height, the larger the IMC thickness, and the more copper atoms are consumed.

Atoms diffused faster under tension with greater solder joint height. H300 was in a state of compression during reflow, while H400 and H520 were higher and in tension. Therefore, for the H520 solder joint, the diffusion speed of Cu atoms from the pad to the solder is the fastest, and the thickness of the interface IMC was the largest.

Figure 2. IMC thickness of solder joints with different heights.

When thermal aging at 230°C for 0.5h, Cu6Sn5 remained solid (the melting point of Cu6Sn5 is 415°C). Therefore, Cu and Sn atoms experienced longer distance solid diffusion on the IMC layer for higher solder joints. Due to the longer diffusion distance, fewer Cu and Sn atoms diffused in the higher SAC305 solder joints after the same diffusion time. In addition, due to the increase in the solder joint height, there were more Cu atoms in the solder. As a result, the concentration gradient between the solder pad and the solder of the high solder joint was smaller, and the atomic diffusion driving force was reduced. Therefore, the interfacial IMC layer growth rate and the Cu pad consumption rate decreased with the increase in the solder joint height.

Shenzhen Fitech has rich experience in the production of solder paste and other solder products and can provide customers with ultra-fine solder paste products (T6 and above) with suitable melting points and performance. Fitech can solve the difficulties of reflow soldering for customers at any time. Welcome to contact us.

Reference

Li, X.M., Wang, L.P., Li, X.W., Li, C., Sun, F.L., Meng, L., Zhu, L. & Li, M. (2022). The effects of solder joint height on the solid–liquid interface diffusion in micro solder joints. Materials Letters. vol. 316.

Back to list

Back to list