Tin Whisker Issue for SnAgCu Solder Paste_Shenzhen Fitech

Tin Whisker Issue for SnAgCu Solder Paste_Shenzhen Fitech

Electronic products often contain various types of chips, which need to form electrical circuits in the form of packaging. In the packaging of electronic products, solder paste, and other soldering materials are mostly used to bond the chip and substrate to realize the electrical path. Due to the excellent bonding effect of tin and copper under heating, tin-based solder paste is mainly used in the field of soft soldering at present. However, tin does not always create benefits. For lead-free solder paste with low silver content (such as SnAg0.3Cu0.7), higher tin content may bring hidden dangers to packaging reliability, such as tin whisker growth.

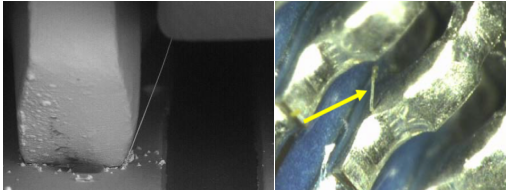

The tin whisker issue is a spontaneous surface defect on pure tin or objects with high tin content, such as solder joints or PCB surface finishes. PCB surface finishes are normally completed through electroplating. If the Sn layer is plated on the bonding pad, tin whisker growth may occur. The length of tin whiskers is quite small, which is commonly between 20-100μm, while it is not excluded that the length can reach the millimeter level in some cases. The driving force of whisker growth on the tin surface can be attributed to the mechanical stress on the tin grain. There are many reasons for the occurrence of mechanical stress, including PCB surface electroplating and the formation of intermetallic compounds (IMCs) by Sn-Cu diffusion. Eventually, the whiskers are extruded from the tin layer after stress release.

Figure 1. Tin whisker appearance.

There are many factors affecting the growth rate of tin whiskers. For example, the Sn contents of SnAg3Cu0.5 and SnAg0.3Cu0.7 solder pastes are both higher than 95wt%, which makes them easy to generate tin whisker growth. However, since the SnAg0.3Cu0.7 solder paste has more Sn content, it is easier to form a large number of tin whiskers. High-temperature aging will accelerate the growth of IMCs in solder joints. For SAC solder paste, Cu6Sn5 IMC will be generated first. With the increase of aging time, the IMC thickness increases, and the IMC grain coarsens. Thus, the compressive stress on the grain is increased. In addition, many people believe that corrosive environments such as high temperatures and humidity will also affect the growth of tin whiskers.

The occurrence of tin whiskers will increase the potential short circuit between components and leads. When tin whiskers form, they usually grow along the path between two conductors, resulting in short circuits and false signals between the paths. The short circuit is an intolerable problem for electronic product manufacturers. Therefore, the emergence of tin whiskers in modern microelectronics is an urgent problem to be solved.

1) Adding lead into the solder paste can alleviate the formation of tin whiskers. Sn and Pb will not react to produce IMCs, which reduces the internal stress inside the solder joints. Therefore, Pb addition in the solder pastes can inhibit the formation of tin whiskers. However, due to the lead-free requirement of solder, Pb addition is not a preferable solution.

2) Adding Bi to SAC solder paste can inhibit the formation of whiskers and reduce the number of long whiskers.

3) Heat treatment at 150℃ for 30-60 minutes.

4) Nickel plating on the bonding pad can slow down the diffusion rate of Cu to Sn, slowing down the growth of tin whiskers.

5) Optimizing the reflow profile to release excess thermal stress.

6) Nano-particles can be added into the solder pastes to slow down the grain coarsening and reduce the stress.

Shenzhen Fitech has a lot of practical experience and technical accumulation in the production of lead-free solder paste. Fitech's solder paste products can effectively solve the tin whisker problem and have excellent mechanical strength and electrical conductivity after soldering. Welcome customers to contact us for more product information and related microelectronic soldering solutions.

Back to list

Back to list