Mechanical Strength of BGA Solder Joint at Low Temperature-Fitech Solder Paste

Mechanical Strength of BGA Solder Joint at Low Temperature

There are some fields involving low-temperature applications of electronic devices, such as aerospace and telecommunications. The electronic devices used on the surface of Mars and the moon should withstand a working environment of less than -100℃. In such a low-temperature operation, the mechanical strength and the thermal and electrical conductivity of the solder joints will be in challenge. Due to the mismatch of thermal expansion coefficient between different materials, there will be a shear load in the solder joint, which may cause the solder joint to fracture.

In order to more intuitively understand the reliability of the solder joints working at low temperatures, Li et al. used BGA structure Cu (Ni)/SAC305/Cu (Ni) solder joints to conduct low-temperature shear tests. The manufacturing of solder joints was completed in a BGA rework machine, with a peak temperature of 250°C and a dwell time of 50s.

After producing SAC305 solder joints, it was observed that the solder matrix was mainly composed of Sn-rich dendrites, Sn, Cu6Sn5, and Ag3Sn. When the solder and Cu pad were interconnected, the IMC at the surface of the solder and pad was Cu6Sn5, while the IMC at the surface of the solder and Ni pads was Ni3Sn4. In general, Ni can inhibit the growth of IMC. Therefore, the IMC thickness of the interface between the solder and Ni pad was smaller.

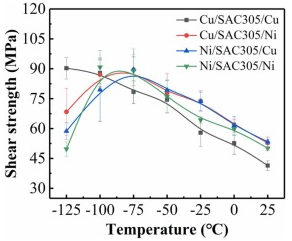

At 25℃, the shear strength of the Cu/SAC305/Cu solder joint was the lowest because the strength enhancement effect of Cu6Sn5 IMC in Cu/SAC305/Cu solder joint on the solder matrix was weaker than that of Ni3Sn4 IMC in the SAC305/Ni pad. Furthermore, it can be seen that the shear strength of Cu/SAC305/Cu solder joints increased with the decrease in temperature. However, the shear strength of the SAC305/Ni solder joint experienced an increasing stage and then began to decline during cooling. The peak shear strength appeared at the temperature of about -75℃.

Figure 1. Shear strength of BGA solder joint at different temperatures.

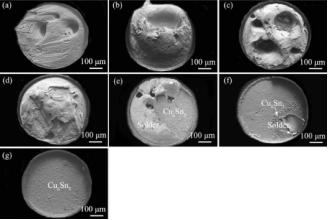

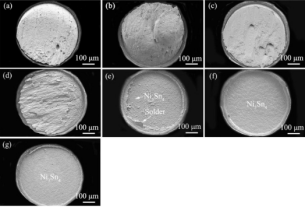

At 25℃, dimples can be seen in the solder matrix, indicating that the fracture tended to occur in the solder matrix. The fracture mode of the Cu/SAC305/Cu solder joint was a ductile fracture. When the temperature dropped to 0°C, −25°C, −50°C, and −75°C, dimples were still found in the solder matrix, and partial fracture occurred at the solder/IMC interface. Hence, both ductile fracture and brittle fracture were presented. When the temperature dropped to -100℃, the IMC at the interface between the solder joint and the pad were fractured, which means that the solder joint was a brittle fracture. For the solder interconnected with the Ni pad, the solder joint still underwent the transition from ductile fracture to brittle fracture with the temperature decreasing.

Figure 2. Fracture surface of Cu/SAC305/Cu solder joint at different temperatures: (a) 25°C, (b) 0°C, (c) −25°C, (d) −50°C, (e) −75°C, (f) −100°C, (g) −125°C.

Figure 2. Fracture surface of Cu/SAC305/Ni solder joint at different temperatures: (a) 25°C, (b) 0°C, (c) −25°C, (d) −50°C, (e) −75°C, (f) −100°C, (g) −125°C.

The medium-temperature solder paste SAC305 produced by Shenzhen Fitech can be used for BGA reballing process, and the solder paste is printed on the pads through a stencil. The melting point of SAC305 solder paste is 217℃, which can be used for the once-reflow of multiple reflows. Moreover, the SAC305 solder joint can maintain excellent mechanical strength at high and low temperatures.

Reference

Li, W.Y., Gui, J., Qin, H.B. & Yang, D.G. (2022). Shear performance of microscale ball grid array structure Cu(Ni)/Sn–3.0Ag–0.5Cu/Cu(Ni) solder joints at low temperatures. Materialstoday Communications, vol.30.

Back to list

Back to list