Automotive LED Application and Packaging - Fitech Solder Paste

Automotive LED Application and Packaging - Fitech Solder Paste

1. Automotive LED application

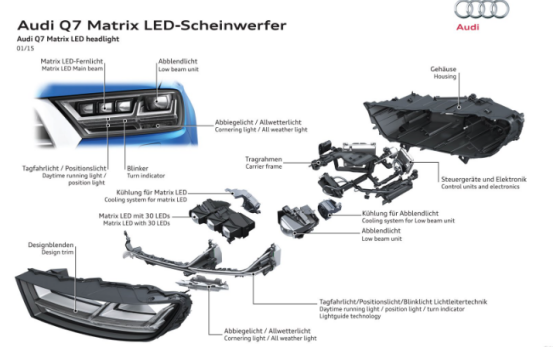

When people are driving in an environment with no light or weak light, it is very dangerous if the cars are without a light source. Therefore, it is compulsory to install high-brightness and reliable headlights on vehicles to help drivers identify all potential dangers on the roads. Compared with halogen lamps, LEDs have better energy efficiency, higher luminous efficiency, and longer service life. Therefore, many automobile manufacturers have begun to use LED as the light source of headlamps, tail lamps, and indicator lamps. In addition, LEDs can be used in display screens, fog lights, etc.

2. Operating principle of automotive LED

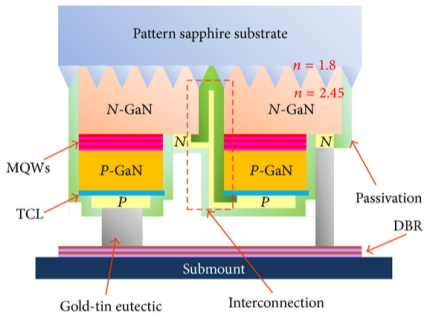

LED module will generate a light source after being powered on. The p-n junction is formed after adding impurities to the two single-crystal semiconductor layers, and electroluminescence occurs in the p-n junction. One of the semiconductor layers combines with the acceptor impurity atoms to produce an n-region with negative electrons, while the other is doped with the donor impurity atoms to form a p-region with positive holes. The active region of light emission is sandwiched between the doped layers. When a forward voltage is applied at both ends of the p-n junction, and the electron encounters a hole, the electron falls from the high-energy conduction band into the low-energy valence band, and excess energy is released in the form of photons.

3. Automotive LED packaging

The LED packaging for automobile headlamps requires the use of SMT substrates. The LED chip is placed on the substrate, and a phosphor layer is formed on the chip to realize wavelength conversion. The two ends of the p-n junction can be connected with the electrical contact through wire bonding or the flip-chip method. The flip chip bonding of LED chips is to place the substrate upward and the p-GaN layer downward on the sub-mount. The LED package is then soldered onto the PCB by a reflow process. The development of automotive LEDs must fully consider the ability of LEDs to withstand high temperatures and electrical stress. Besides, the LEDs should be able to withstand all expected vibrations and mechanical impact and maintain operation after long-term aging.

The solder paste can be transferred to the PCBs for bonding with the LED using the SMT printing process, and then the LED package is pasted on the solder paste layer. The printed solder paste can be placed on the pad through the stencil apertures using a pre-perforated stencil. The size of the apertures and the thickness of the stencil are related to the particle size of the printing solder paste. The size and pitch of automobile LED chips are small, and it is often necessary to use ultra-fine solder paste (T6 and above). After the solder paste point preparation and LED packaging and mounting, the PCBs will be sent to the furnace to complete reflow soldering.

4. Automotive LED packaging solder

The printing solder paste products produced by Shenzhen Fitech include low-temperature (SnBi57.6Ag0.4), medium-temperature (SAC305), and high-temperature (SnSb10, Au80Sn20) series. According to the soldering temperature of different automobile LEDs, customers can choose the corresponding products. Fitech’s solder paste products have the advantages of excellent printability, stable viscosity, long onboard time, and high mechanical strength, which makes them meet the packaging and soldering requirements of highly reliable automotive LEDs. Welcome to contact us for cooperation.

Back to list

Back to list