Void Caused by Solder Paste Properties and Improper Reflow_Fitech solder Paste

Void Caused by Solder Paste Properties and Improper Reflow_Fitech solder Paste

In the production process of electronic products, it is difficult to eliminate voids in solder joints. There are many reasons leading to voids, including vapor accumulation and solder paste oxidation during soldering. The size and number of solder joint voids will have a negative impact on the solder joint reliability. Aerospace, military industry, rail transit, automotive electronics, and other fields have a low tolerance for void ratio. For example, they will stipulate that the solder joint void ratio must be less than 5%.

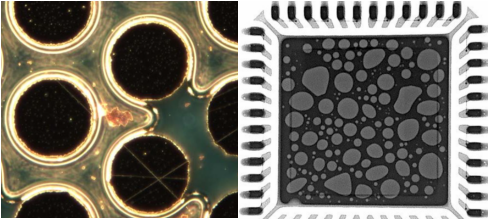

Figure 1. Void appearance.

1. Mechanism of vapour accumulation during soldering

Flux provides solder paste with different wettability and chemical activity, but during soldering, the volatilization of flux and the removal of oxide will generate vapor. In general, the voids in solder paste are closely related to the flux composition of solder paste. The mechanism of voids formed by a chemical reaction in solder paste during soldering can be roughly divided into three categories.

(1.1) The reactions between flux and metal oxides (SnO/CuO) produce water vapour

2RCOOH + SnO → (RCOOH)2Sn + H2O

CuO + 2HBr → CuBr2 + H2O

(1.2) Organic acid esterification reaction of flux generates water vapour

RCOOH + R’OH → RCOOR’ + H2O

(1.3) Gas generated by pyrolysis of organic matter at high temperature

2. Effect of reflow process on void genreation

Flux plays the role of wetting the solder pads and changing the surface tension of the solder pads during reflow. However, the excess flux and water vapor generated by the reaction require sufficient time to leave the solder joints. Hence, the influence of the reflow process cannot be ignored. When reflow soldering, flux requires sufficient time to remove the oxide layer and reduce surface tension. If the soak zone duration is insufficient, the oxide layer cannot be completely removed, or the volatilization of the flux is limited. On the contrary, a long soak zone time will easily lead to a lack of flux activity and high void volume.

For the ultra-fine (T6 and above) solder paste, the fine particle size makes it extremely easy to be oxidized, and the oxidation of solder paste will result in locally poor solderability and voids. The input of nitrogen atmosphere during reflow is a way to diminish the oxide formation and reduce void volume.

3. Solder paste with low void volume

After 20 years of solder paste R&D and application experience, Shenzhen Fitech can manufacture ultra-fine solder paste products (T6 and above) with excellent wettability, tackiness, viscosity stability, low void ratio, and high mechanical strength, which can meet the requirements of the large-scale production of ultra-fine-pitch electronic components. Please let us know if you need more information.

Back to list

Back to list