Tin Whisker Growth of SAC305 Solder Paste in Corrosive Environment_Shenzhen Fitech

Tin Whisker Growth of SAC305 Solder Paste in Corrosive Environment

Sometimes white whiskers can be found at the solder joint of SMT devices. This is probably due to the growth of tin whiskers on the leads. The occurrence of tin whiskers may cause short-circuit problems. Tin whisker is a natural phenomenon in tin-containing solders. The tin content in SAC305 solder paste reaches 96.5wt%. Such high tin content will more or less lead to the growth of tin whiskers. The fundamental factor affecting the formation of tin whiskers is the accumulation of internal stress in solder joints. For example, when components are exposed to a high humidity environment, they are easy to be corroded by water vapor and form stress in the tin layer, resulting in the appearance of tin whiskers. Since electronic products are sometimes inevitably exposed to a corrosive environment, it is necessary to study the growth mechanism of tin whiskers under corrosive conditions.

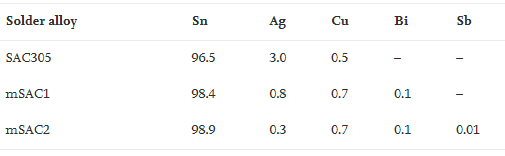

Illes and Horvath carried out a damp heat test (85 ℃/85% RH) for SAC305 solder paste on the FR4 boards with immersion tin, and the test time was 3000h. The solder paste was printed on the boards, and several 0805 resistors were mounted. In addition, Illes and Horvath compared SAC305 with the other two solder pastes (mSAC1 and mSAC2 (Table 1)).

Table 1. Solder paste alloy compositions.

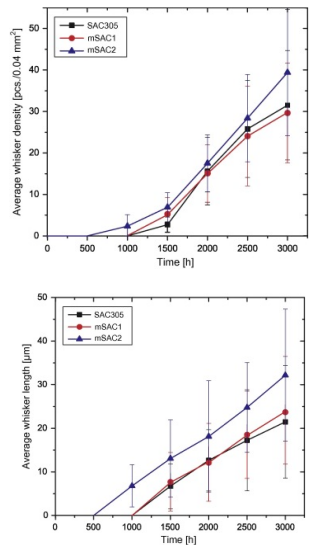

After conducting the damp heat test for 3000h, nodular-type tin whiskers were observed on SAC305 solder joints. No whiskers were found in the SAC305 solder paste before the test time reached 1000 hours, but after that, the whiskers began to appear and increase with time and showed a monotonous upward trend. Compared with mSAC1 and mSAC2. The final average tin whisker density of SAC305 solder paste was between mSAC1 and mSAC2. The average tin whisker density difference between these three solder pastes was very small for 1500-2500 hours. Furthermore, the mSAC1 and mSAC2 tin whisker densities showed a monotonic increase with the increase in test time, but the growth trend of mSAC2 was faster.

Figure 1. Average whisker density and length after damp heat test.

The final average tin whisker length of SAC305 was between that of mSAC1 and mSAC2, reaching 24μm, which was far less than mSAC1. Therefore, it reveals that the SAC305 solder paste and mSAC1 have a higher resistant to whiskering. In order to compare the tin whisker formation under different humidity, Illes and Horvath also placed the test boards in the environment of 85 ℃/20% RH for the tin whisker test. The conclusion is that tin whiskers do not appear when the humidity was reduced to 20% RH.

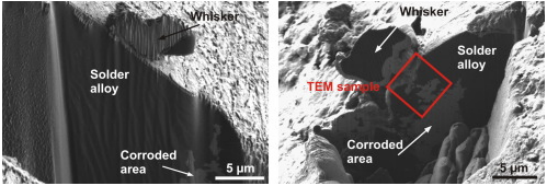

After the solder joints were corroded, the excessive Sn atoms were pushed within the Sn layer and produced local stress and excessive strain energy. Specifically, the SnOx oxide layer is formed on the surface of the Sn-rich solder joint after corrosion and oxidation. The formation of the oxide layer will lead to volume expansion and mechanical stress on solder joints. Illes and Horvath observed that the corrosion areas under SAC305 whiskers were much smaller than that under mSAC2 whiskers. Due to the small corrosion area, the stress in the SAC305 solder joint was smaller, and a smaller amount of tin whiskers was formed

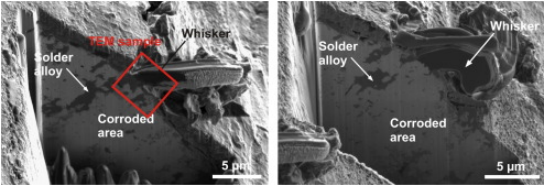

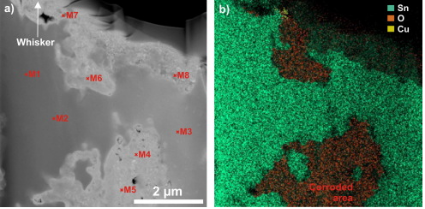

Through observing the TEM image of the SAC305 corrosion area, it can be found that the oxygen content in the corrosion areas was more than 30at%. Furthermore, there was a small amount of copper precipitation in the M7 area. The occurrence of copper precipitation led to volume expansion, which increased local mechanical stress.

Figure 2. The corrosion conditions of SAC305 and mSAC2.

Figure 3. TEM and EDS images of SAC305 corrosion area after damp heat test: left: TEM image; Right: EDS image.

Shenzhen Fitech has rich experience in the production and customer application of SAC305 ultra-fine solder paste (T6 and above) and can control the growth of whiskers in the solder paste well. Fitech's SAC305 ultra-fine solder paste has excellent weldability and can maintain reliable mechanical strength after aging. Please contact us for more product information.

Illes, B. & Horvath, B. (2014). Tin whisker growth from micro-alloyed SAC solders in corrosive climate. Journal of Alloys and Compounds, vol.616, pp.116-121.

Back to list

Back to list