Application of Conductive Paste in Electronic Textiles_Shenzhen Fitech

Application of Conductive Paste in Electronic Textiles_Shenzhen Fitech

With the improvement of people's quality of life and the development of flexible electronic technology, many manufacturers have tried to combine electronic technology with flexible textiles to bring people a more intelligent life. Choosing suitable soldering materials is a difficult problem for electronic textile developers. Since electronic textile circuits typically need to meet high temperature and tensile requirements, the soldering materials need to have excellent ductility.

Conductive paste material

To find a suitable conductive coating material for electronic textiles, Wu et al. attempted to adopt a method of combining epoxy resin and rosin to meet the requirements of high temperature and solder joint strength. The resin they prepared consists of 55 wt% epoxy resin (bisphenol A diglycidyl ether) containing 1.5 wt% rosin, 14 wt% butyl carbitol acetate, 18 wt% methyl methacrylate, and 13 wt% n-butylamine. The conductive paste is composed of 85wt% silver-plated copper powder (AgCu) and 15wt% resin. In addition, Triton X-100 was added to significantly reduce the viscosity of the conductive paste.

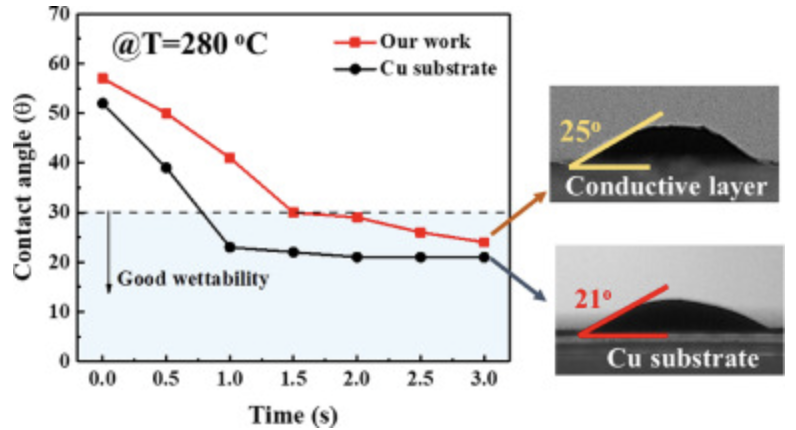

Interestingly, heating and curing the resin at 115℃ can achieve cross-linking of the epoxy resin/butylamine mixture, enabling it to maintain better chemical stability during high-temperature welding. Meanwhile, mixing epoxy resin with a small amount of rosin can achieve a smaller contact angle, which is conducive to soldering reliability.

Experimental result

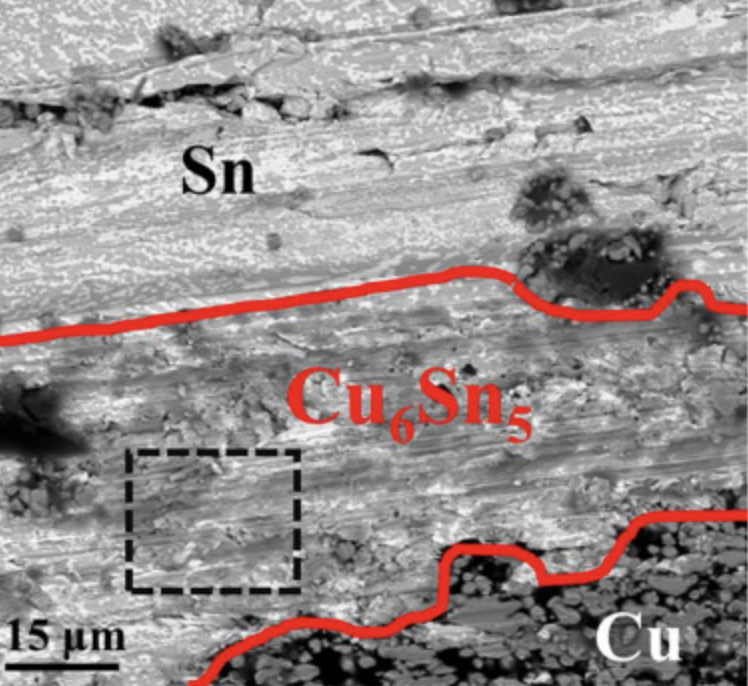

The conductive paste can be coated on the substrate by steel screen printing. The resin and AgCu particles in the conductive paste form a conductive coating on the circuit after heating. Conductive coatings have good compatibility with solders. When using a soldering iron to deposit solder melts on the surface of a conductive coating, the molten solder will quickly diffuse onto the conductive coating (with a small contact angle). After solidification, an intermetallic compound Cu6Sn5 is formed at the interface between the conductive coating and the solder to promote the adhesion of the solder. Due to the low content of Ag particles, there is no intermetallic compound Ag3Sn present at the interface.

Figure 1. Contact angle between conductive coating and solder.

Figure 2. Intermetallic compound at the interface between solder and conductive coating.

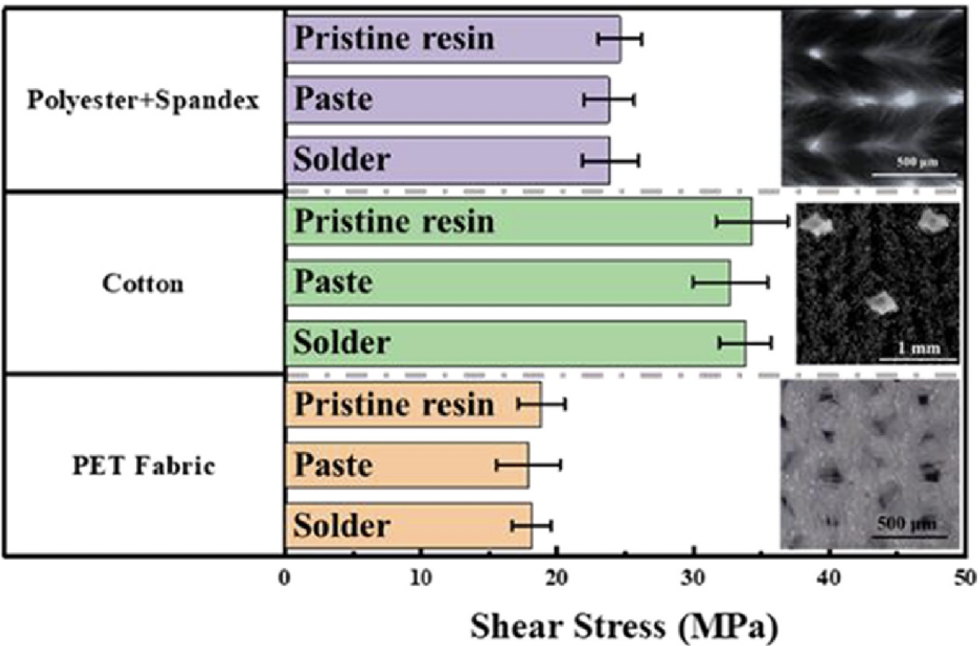

Shear force is an important criterion for judging soldering reliability. On different fabric substrates, the shear strength of the cured conductive coating can reach over 20 MPa. Due to the deep penetration of the paste, the lap shear strength of the fabric exhibits better adhesion. The ductility performance of the conductive paste is acceptable. During the stretching process, due to the strong adhesion to the braided wire, the resistance of the printed structure rapidly increases until the stretching is greater than 30%.

Figure 3. Shear strength of the conductive paste.

Reliable solder pastes

Shenzhen Fitech is committed to providing customers with high-reliability solder. Fitech’s lead-free solder pastes and anisotropic conductive pastes have excellent mechanical strength and drop resistance and are suitable for many packaging fields, such as micro optoelectronic displays, aerospace, automotive electronics, etc. Welcome to contact us for more information.

Reference

Back to list

Back to list