MEMS Laser Soldering

MEMS Laser Soldering

With the development of integrated circuits, a variety of soldering techniques have been developed to meet the soldering of small components. The advent of laser soldering allows small-size component soldering with better efficiency and precision. Laser soldering technology develops rapidly and is adopted by more and more semiconductor manufacturers.

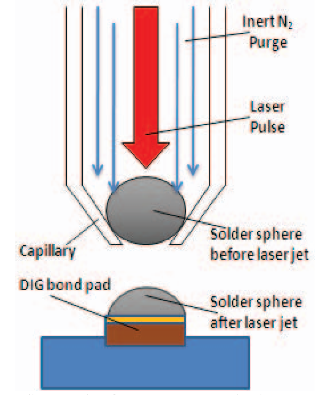

Micro-bumps can be made on the chip with the ball-attach process, and the chip and the substrate can be connected. The popular soldering methods used in MEMS are reflow soldering and laser soldering. Both techniques are widely used for semiconductor packaging. As shown in the figure below, the solder balls ejected by a laser emitter form micro-bumps on the chip. Unlike step heating of reflow soldering, the laser beam can realize local heating. The laser beam focused by a lens has a high energy density and irradiates a local area to undergo high-temperature soldering. Laser soldering completes in seconds. The laser beam has a wavelength of 900-980nm. In addition, it can achieve flexible movement in space by changing the laser emission angle. As a result, laser soldering is an outstanding choice for MEMS components.

Figure 1:Laser Soldering

The laser soldering process mainly includes solder paste preheating and the connection of solder paste and pad by laser. The micromechanical structure of MEMS is easily damaged by stress. A laser can heat the solder paste precisely and quickly, resulting in little thermal shock, which effectively ensures the solder joint reliability. Different from IC components, MEMS are highly sensitive to the environment. The impurities in the application environment may affect the component's accuracy. There is little residue generation after soldering, significantly reducing damage to the accuracy of devices.

In encapsulation, a laser can form a high heat source to join the cap to seal the MEMS component. Laser soldering can apply to various caps such as ceramic or metal. The resulting thermal stress is very low, effectively protecting the internal components.

Back to list

Back to list